This is a new Tutorial series on DELTA Motion Control’s RM200 Lite – CPU20L. The first Tutorial introduces Delta Motion Control’s RM200 Lite and explains tool installation, creating a new project and CPU connection.

Let’s get started!

Hardware In my Tutorial

This is the Hardware used in this article.

- R200-B5L is the 5 Slot board for the RMC200

- CPU20L is the RMC200 Lite main unit

- U14 is a multi-function IO Module

- R2-SC is a Cover to protect unused Slots

RMC200 Lite?

The RMC200 Lite used in this article is a controller with all the same control features as the RMC200 Standard, capable of controlling up to 18 axes and supporting up to 40 reference inputs.

The RMC200 Lite is a compact, powerful and economical CPU with an integrated power supply module. Furthermore, the RMC200 Lite uses a dedicated base module, resulting in a more compact footprint, lower power consumption and lower cost.

And the RMCTools software for building RMC200 Lite projects is the same as for the RMC200 Standard, RMC150 and RMC75.

CPU20L?

CPU20L is a CPU in the RMC200 Lite series, a compact CPU with up to 18 axes, 24 VDC input, 28 W power supply, USB, two Ethernet ports, Display Screen, 2 x inputs and 2 x outputs with built-in system.

Communication

The RMC200 Lite Motion Controller integrates easily with PLCs, PCs and HMIs. Its CPU is embedded with Ethernet x2 (100 Mbps) and supports star, linear and ring topologies.

Protocol

The RMC200 Lite Motion Controller supports the following Industrial Protocols.

- EtherNet/IP

- PROFINET

- Modbus/TCP

- CSP (Allen-Bradley)

- FINS (Omron)

- Procedure Exist (Mitsubishi)

- DMCP (Delta Motion Control Protocol)

- RMCLink and LabView (for PCs and HMIs)

Discrete I/O

The inputs and outputs of the RMC200 Lite Motion Controller can be used to trigger RMC user programmes or to communicate simple data such as error or completion signals.

USB Port

The RMC200 Lite Motion Controller has a high-speed USB 2.0 port (480 Mbps) for use with RMCTools software, RMCLink ActiveX and .Net assembly.

RMC Tools?

RMCTools is software for configuring, tuning, troubleshooting, programming and controlling the functions of Delta Motion Control’s RMC70, RMC150 and RMC200 motion controllers. For example,

- Monitor all axis status registers and modify parameters

- Plot up to 48 registers with RMC200 Lite and up to 128 registers with RMC200 Standard

- Events such as parameter changes, commands, errors and communications can be logged

- User Program for creating command combinations only

- Graphical creation of custom motion profiles and cam profiles

Download Tools

Download RMCTools for the RMC200 from the Link below.

https://deltamotion.com/dloads/downloads.php

Download the 64Bit or 32Bit Setup File according to the PC on which you want to install RMCTools.

EXE File is downloaded.

Installation

Double-click the RMCTools Setup File that you have just downloaded from the Delta Motion Control HP to start the installation.

Set the Location where RMCTools is to be installed and proceed with Next.

Start the set-up with Install.

just wait a while..

Done!

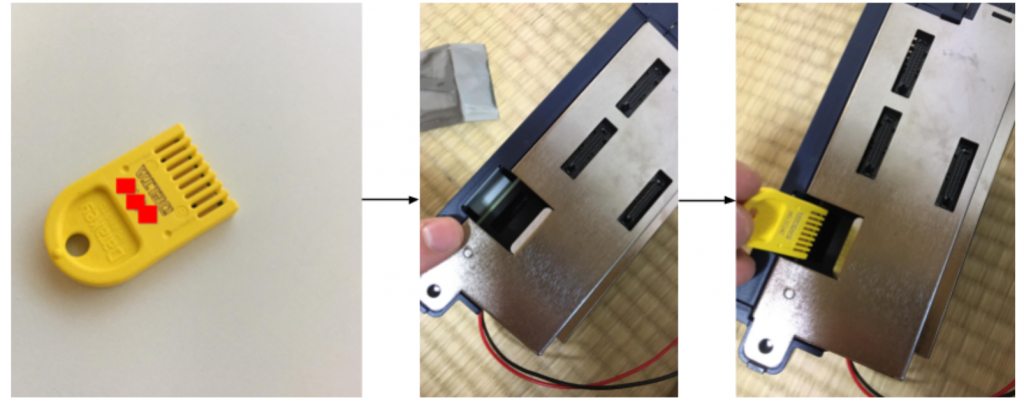

Install Feature Keys

Feature Keys are removable and attachable keys on the CPU module that allow the control functions of the RMC200 to be specified. This makes it easy to transfer control functions from one RMC200 CPU to another when replacing the current RMC200.

The Feature Key, when first purchased, already contains the ordered functions. It is also possible to add functions to the Feature Key later.

Control Loop

The control loops defined in Feature Keys define the number of control axes; the maximum Control Loop depends on the CPU model: 36 for CPU20L Lite and 100 for CPU40 Standard.

The calculation of the number of Control Loops required for each axis is as follows.

Single-loop axis: 1 control loop

Axis is the case where only one quantity is controlled, e.g. position only or force only.

Dual-loop axis: 2 control loops

An axis is a case of controlling two quantities, e.g. position and force.

Reference axis: 0 control loops

Axis with inputs only and no control outputs; also called half-axis in RMC 200.

Virtual axis: 0 control loops

A type of reference axis, where there is no input or control, but the case provides virtual motion.

Output only axis: 0 control loops

This is the case for axes with analogue outputs only.

Video

You can check the state of CPU20L with the Feature Key installed from this video.

https://youtube.com/shorts/N-lbn_OS3Tk

Launch Tools

Start RMCTools.

Done!

Connect the USB

Connect the USB Port on the CPU20L to the PC.

Connect the A to B USB cable to the USB port on the PC and the RMC200. This USB cable is commonly used for PC peripherals such as printers and can be purchased from electronics retailers.

New Project

Once RMCTools has started, create a new project using File>New>Project.

Enter a Project name and set a location to save the Project > Click on the Finish button to proceed.

If you are using RMCTools for the first time, the following security settings screen will appear.

Click Allow access to proceed.

Next, enter the CPU name and proceed with Next>.

Set the communication medium between PC and CPU. This time use USB.

After a short wait, the R200-CPU20L used in this article was found.

Check the Upload all settings from this controller checkbox to ensure that the settings currently in Hardware are uploaded.

Done!Now RMCTools has connected to the CPU. When it does, the text Online (Disbaled) is displayed. (Actually, the character displayed by RMCTools depends on the CPU status.)

CPU20L and U14 installed in this article were displayed in Modules.