This is a new series where we’ll be covering various topics using FATEK’s SC Series SERVO. We’ll start by introducing the basics: tool installation, operation, connection, and download.。

Alright, let’s enjoy the FA.

Foreword

Thank you from the bottom of my heart for visiting my technical blog and YouTube channel.

We are currently running the “Takahashi Chris” radio show with Full-san (full@桜 八重 (@fulhause) / X) which I deliver every Wednesday night.

Sharing, not hoarding, technical knowledge

We publish technical information related to factory production technology and control systems for free, through blogs and videos.

With the belief that “knowledge should be accessible to everyone,” we share practical know-how and real-world troubleshooting cases from our own field experience.

The reason we keep it all free is simple: to help reduce the number of people who struggle because they simply didn’t know.

If you’ve ever thought:

- “Will this PLC and device combination actually work?”

- “I’m having trouble with EtherCAT communication—can someone test it?”

- “I want to try this remote I/O, but we don’t have the testing environment in-house…”

Feel free to reach out!If lending equipment or sharing your configuration is possible, we’re happy to verify it and share the results through articles and videos.

(We can keep company/product names anonymous if requested.)

How can you support us?

Currently, our activities are nearly all unpaid, but creating articles and videos takes time and a proper testing environment.If you’d like to support us in continuing and expanding this content, your kind help would mean a lot.

Membership (Support our radio show)

This support plan is designed to enhance radio with Mr Full.

https://note.com/fulhause/membership/join

Amazon Gift List (equipment & books for content production)

Lists equipment and books required for content creation.

https://www.amazon.co.jp/hz/wishlist/ls/H7W3RRD7C5QG?ref_=wl_share

Patreon (Support articles & video creation)

Your small monthly support will help to improve the environment for writing and verifying articles.

https://www.patreon.com/user?u=84249391

Paypal

A little help goes a long way.

https://paypal.me/soup01threes?country.x=JP&locale.x=ja_JP

Just trying to share things that could’ve helped someone—if only they’d known.

Your support helps make knowledge sharing more open and sustainable.

Thank you for being with us.

soup01threes*gmail.com

Technical knowledge shouldn’t be kept to ourselves.

Reference Link

http://soup01.com/en/category/fatek_en/

Specifications

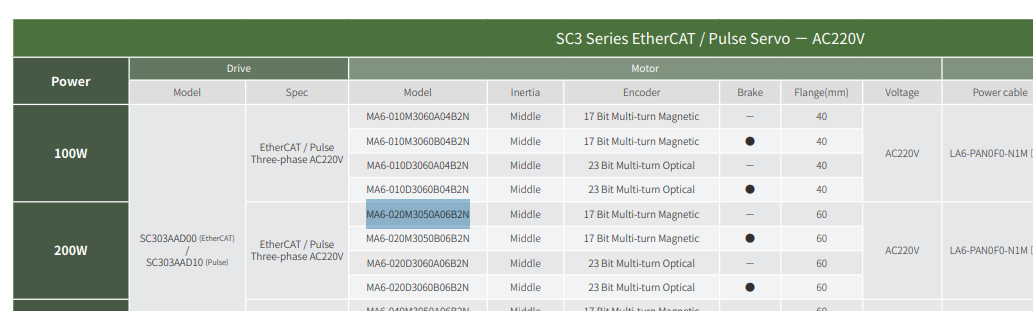

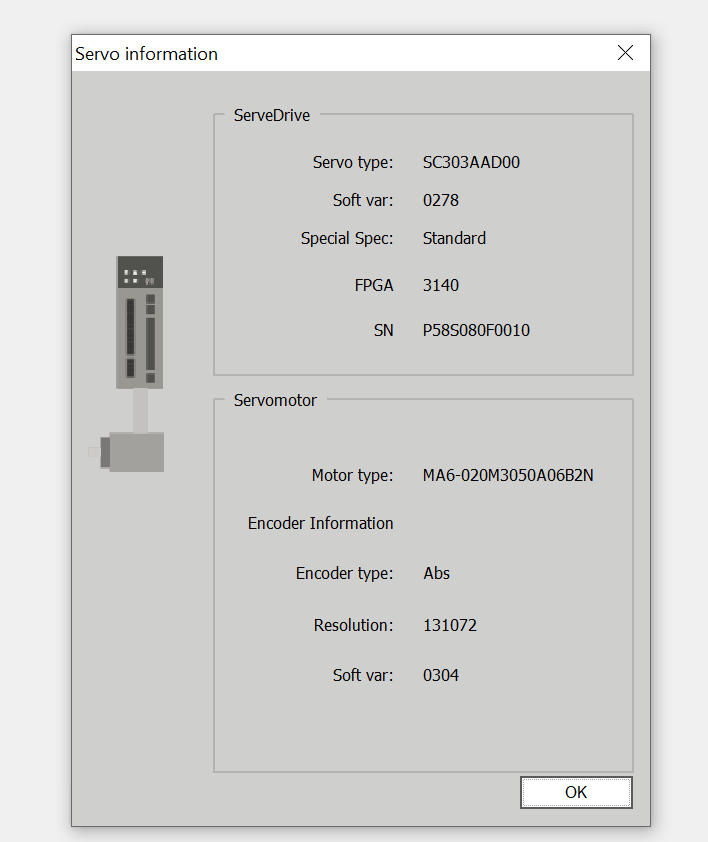

The SERVO used in this article is the MA6-020M3050A06B2N, a 220V model equipped with a 17-bit encoder.

Wiring Example

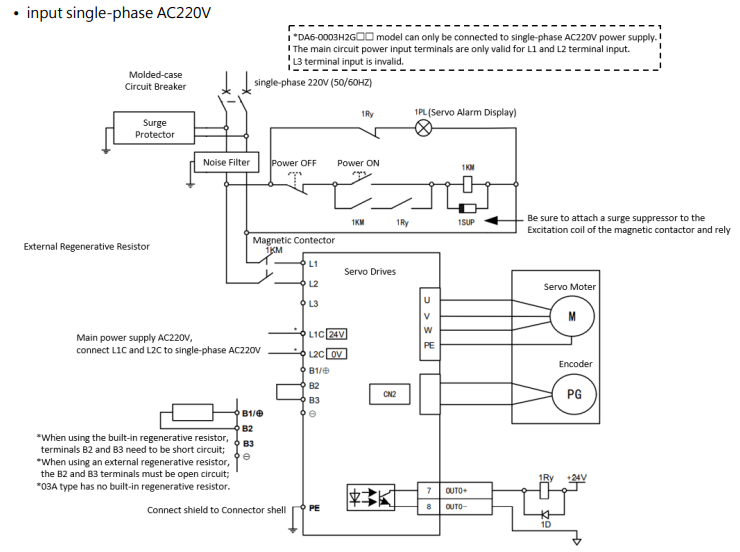

This is a wiring example for using the SC3 Servo Series in single-phase operation.

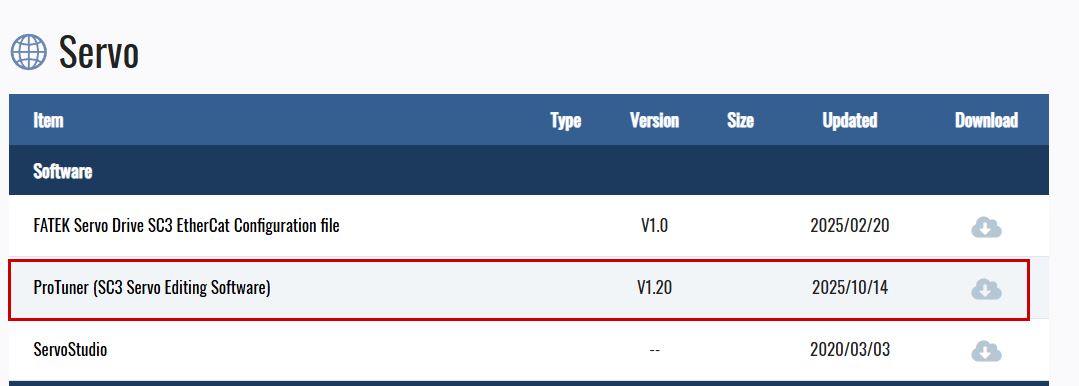

Tool Download

Please download the setup for the SERVO adjustment tool ProTurner from Fatek’s website.

Tool Installation

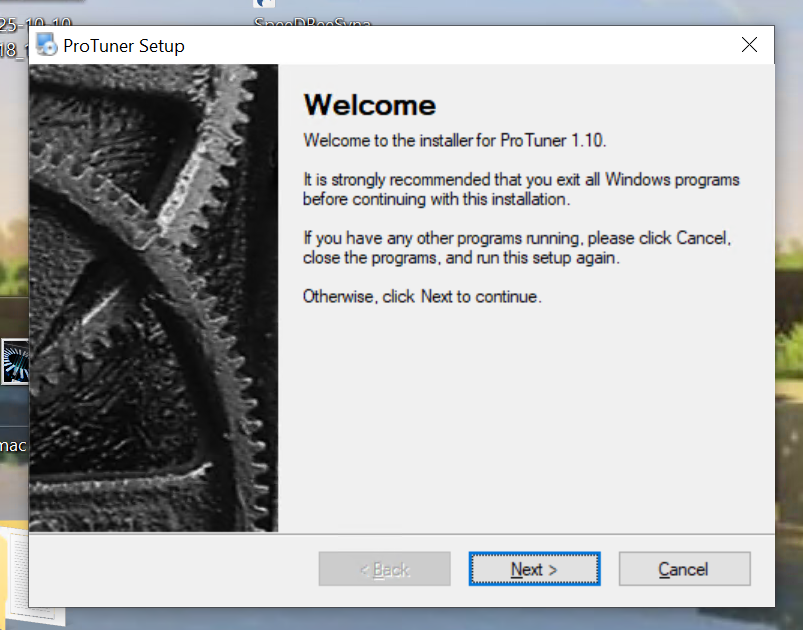

Launch the setup file for the ProTuner tool you downloaded earlier.

Next> to proceed.

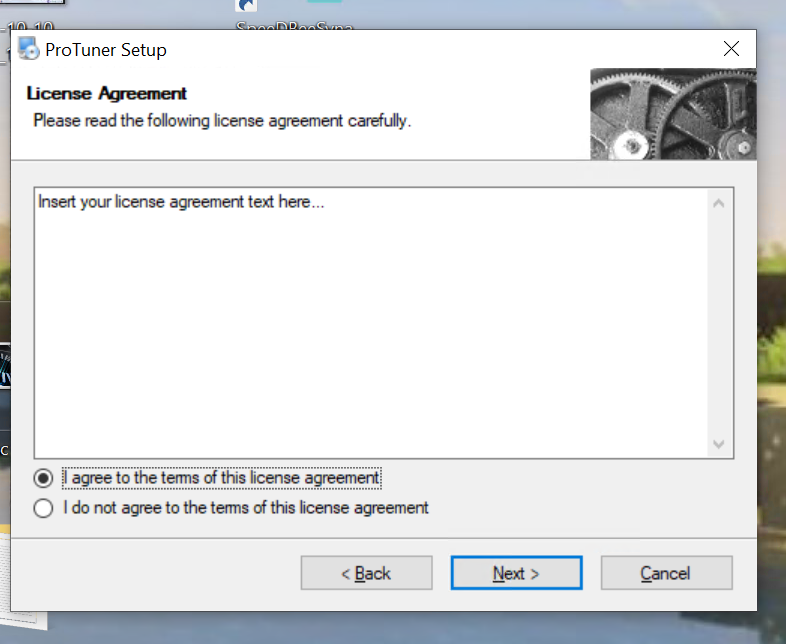

Agree to the license and proceed with Next>.

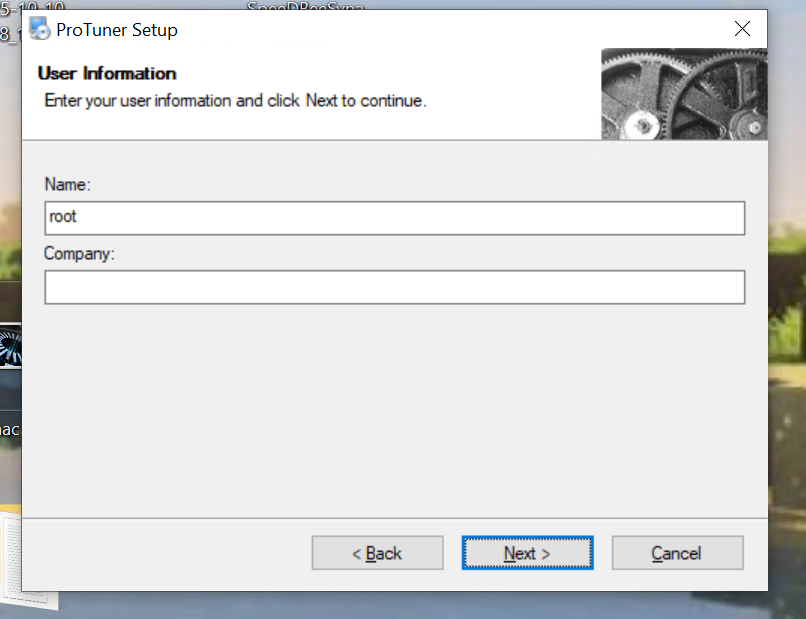

Enter your company information and proceed by clicking Next>.

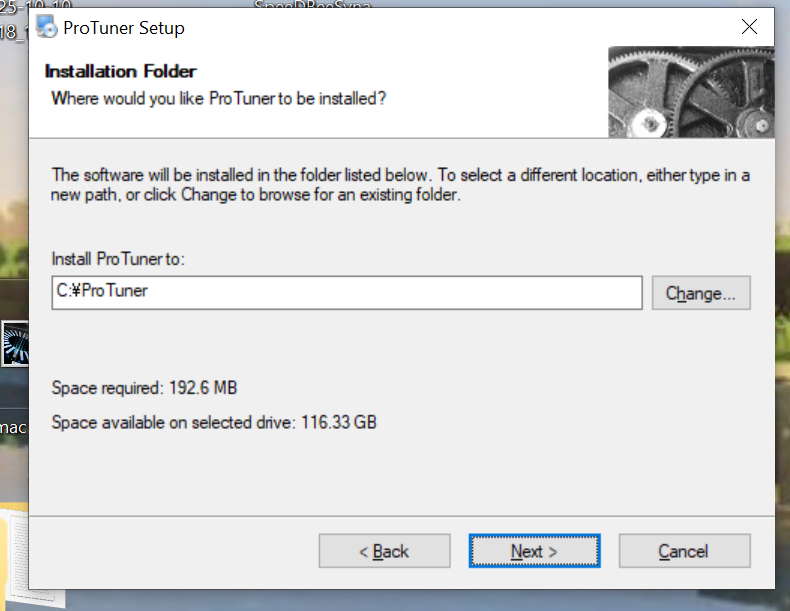

Next> to proceed.

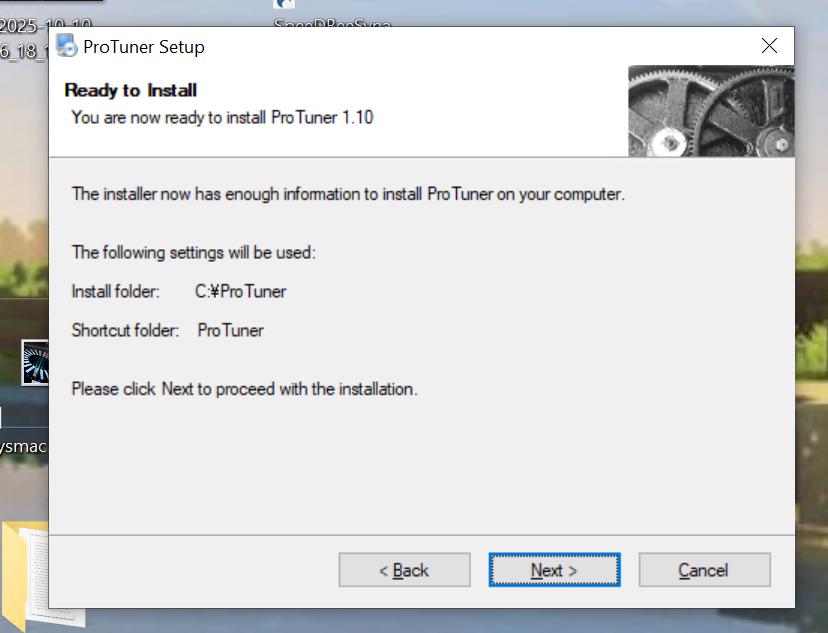

Next> Let’s proceed further.

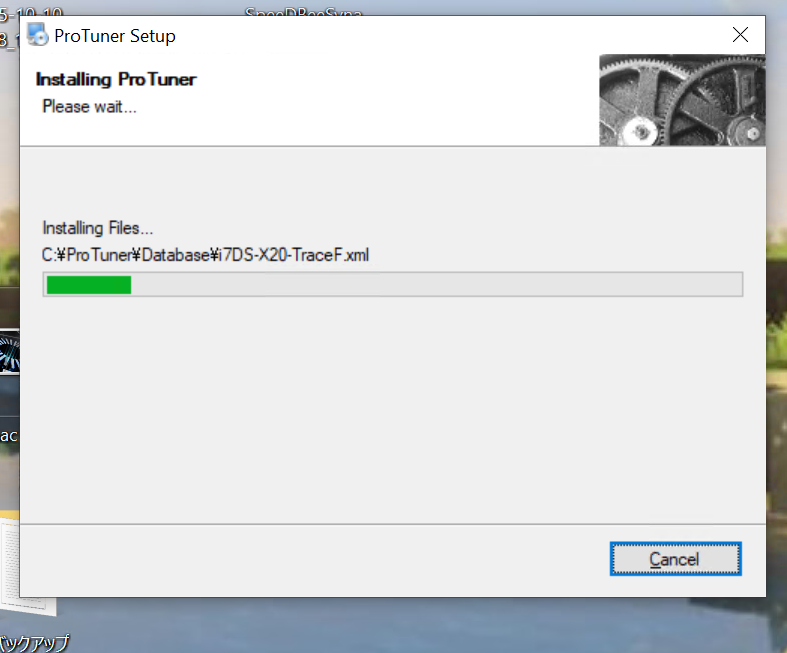

Next> to proceed.

Please wait a moment.

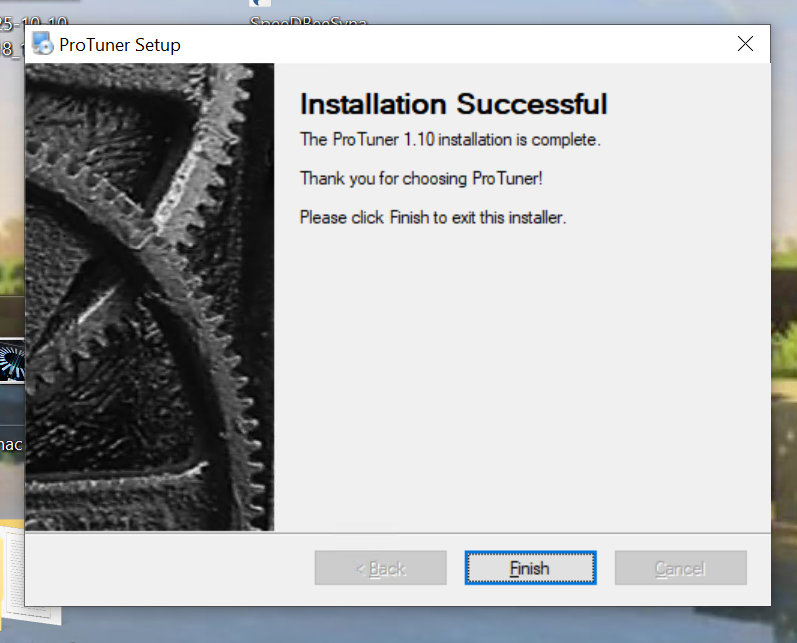

Done!ProTuner has been installed.

Launch The ProTuner

Now let’s launch the ProTuner tool.

Please wait a moment…

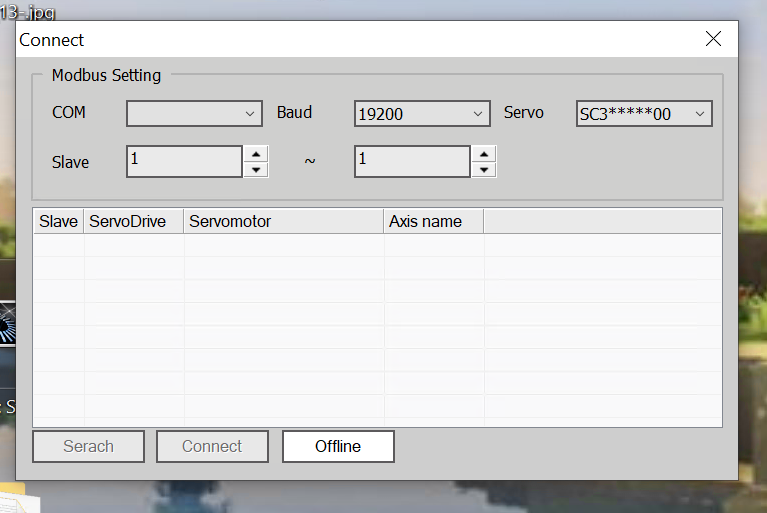

Done!The ProTuner Servo Drive Connection screen will appear.

Connection

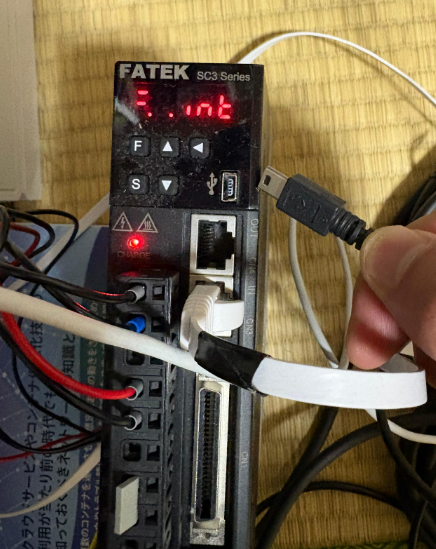

Connect the FATEK SERVO DRIVE to the PC via USB

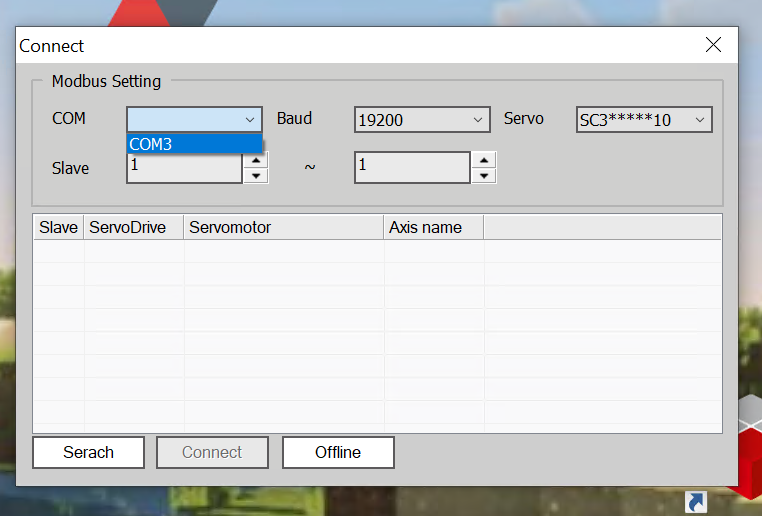

Select the appropriate COM port from the COM drop-down list.

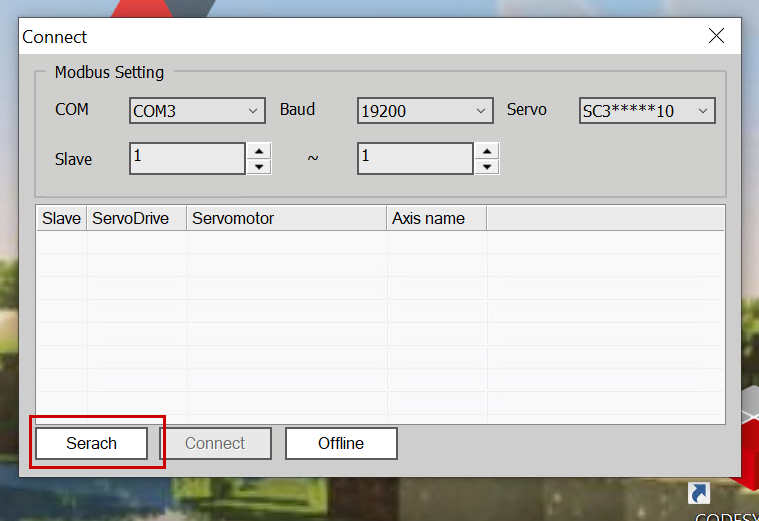

Next, click the Search button.

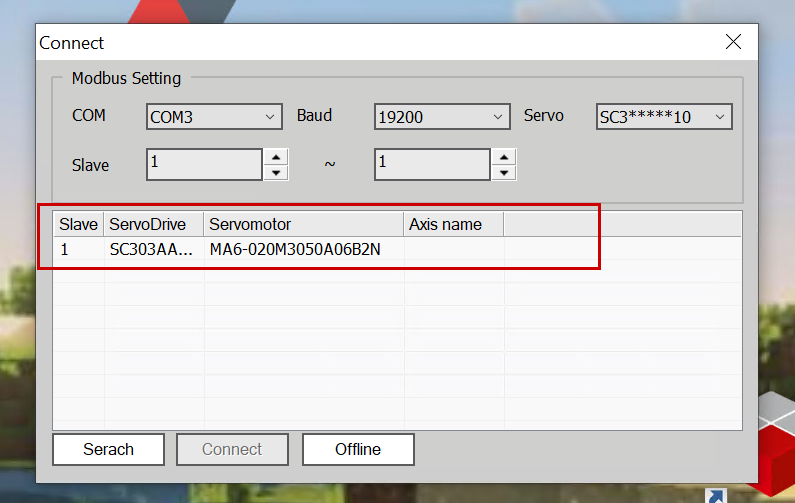

Done!We were able to locate FATEK’s SC series SERVO.

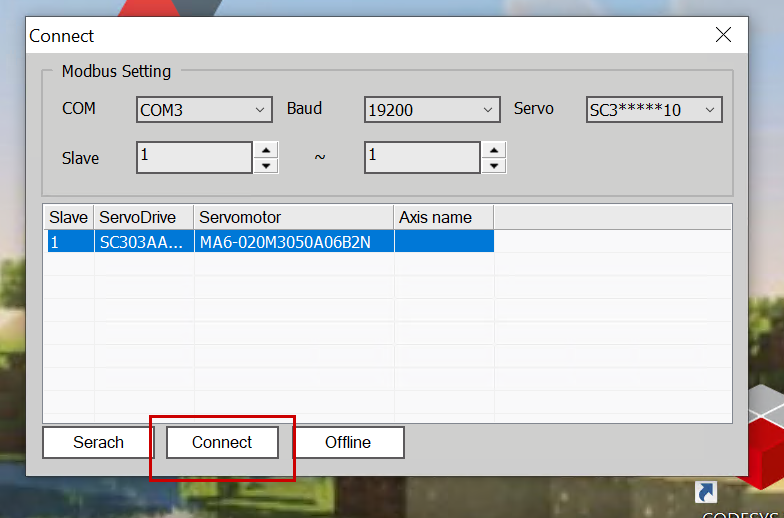

Next, click the Connect button to connect the SERVO and PC.

Done!

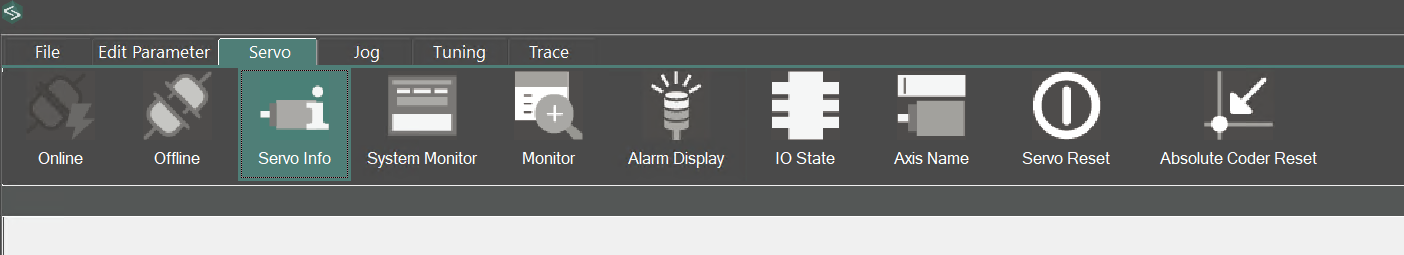

Servo Information

Click Servo→Servo Info to view the current SERVO motor information.

Done!As shown in the figure below, you can check information such as the model and resolution of the SERVO DRIVE and motor.

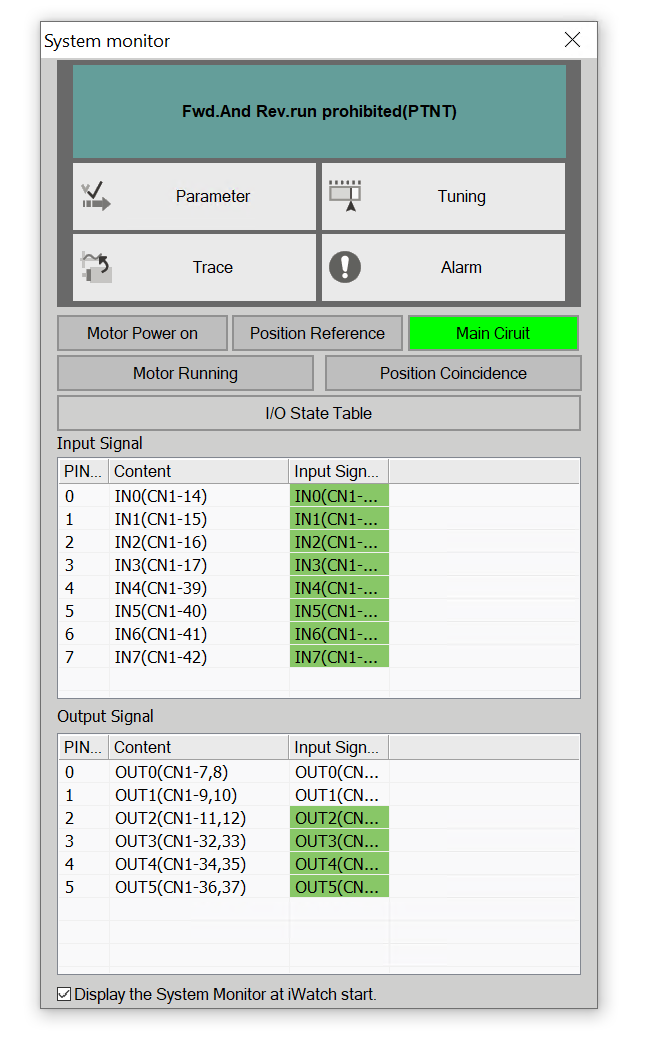

System Monitor

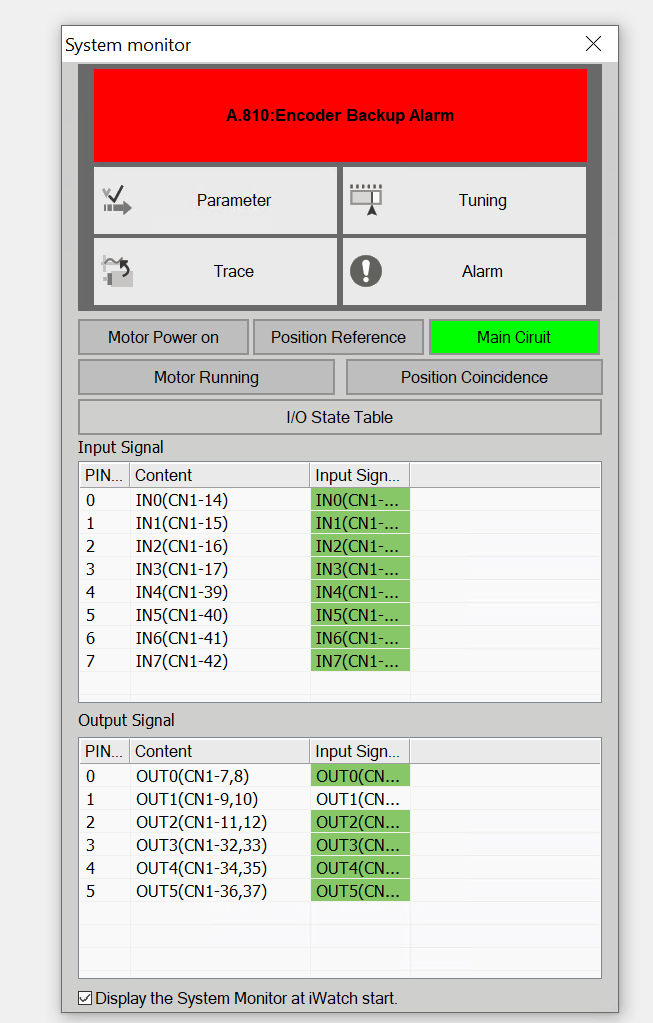

Next, click Servo→System Monitor.

This allows you to check the current status of SERVO alarms, I/O terminals, and other components.

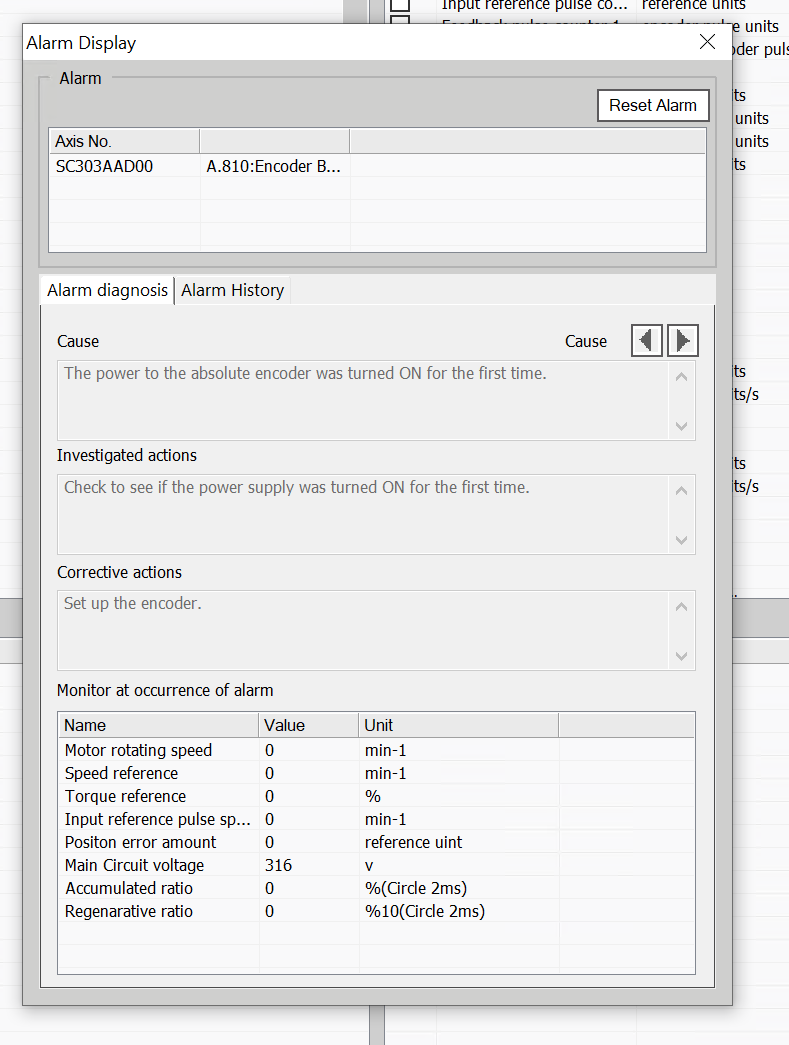

Alarm Display

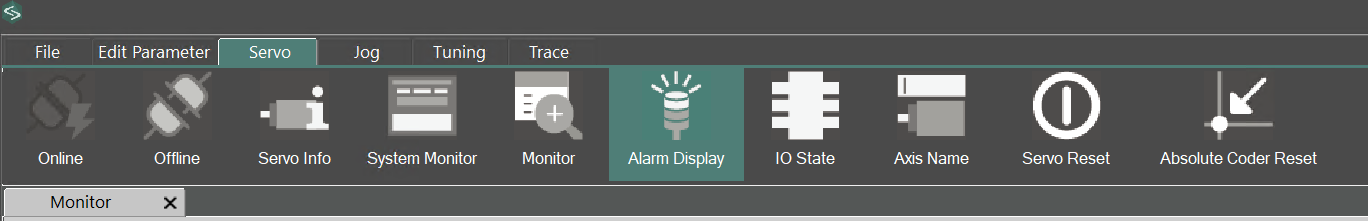

Click Servo→Alarm Display.

You can check or reset the SERVO alarm information.

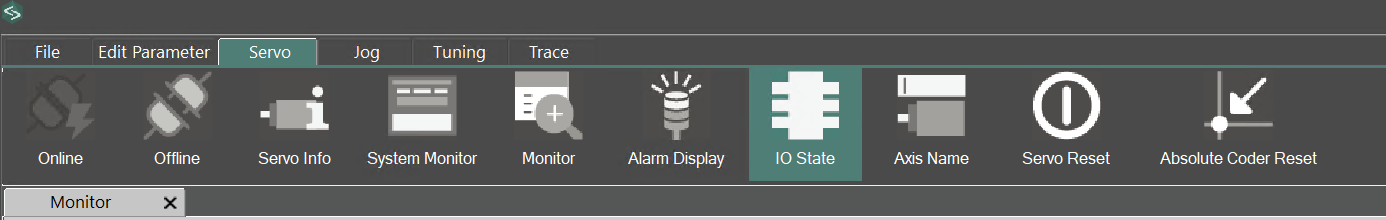

IO state

Click Servo→IO State to check the current input/output status of the SERVO DRIVE’s IO terminals.

Axis Name

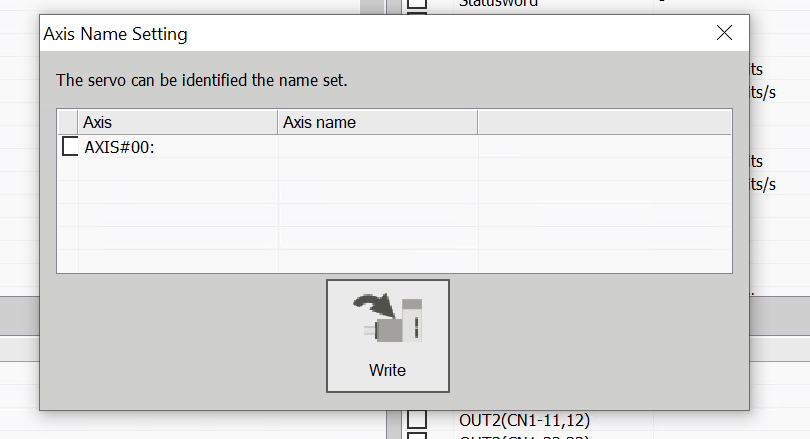

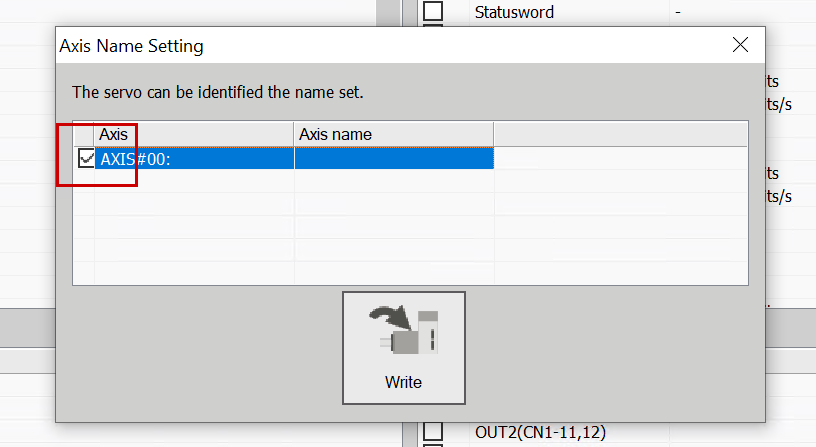

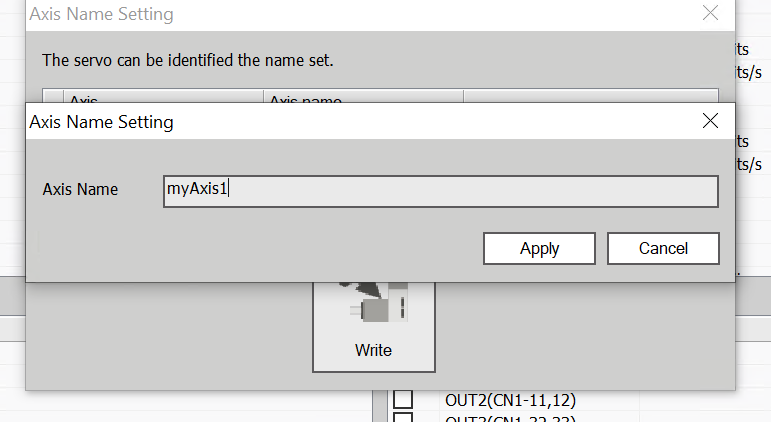

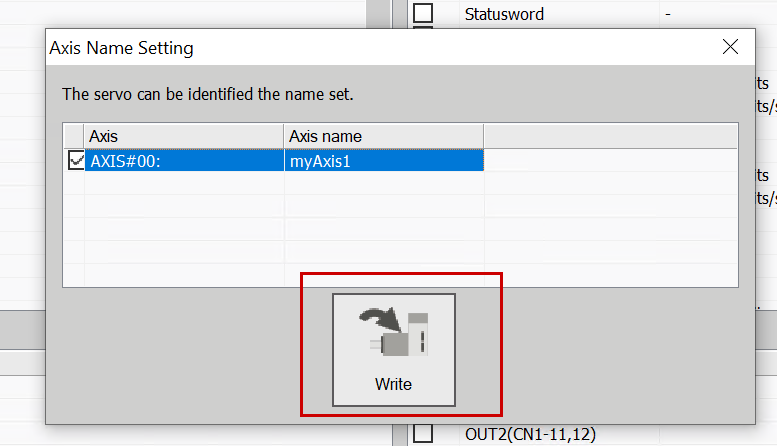

You can set or check the name of the currently connected servo under Servo→Axis Name.

Place the checkbox next to the axis.

Then click the Axis Name field.

Set the Axis name → Apply.

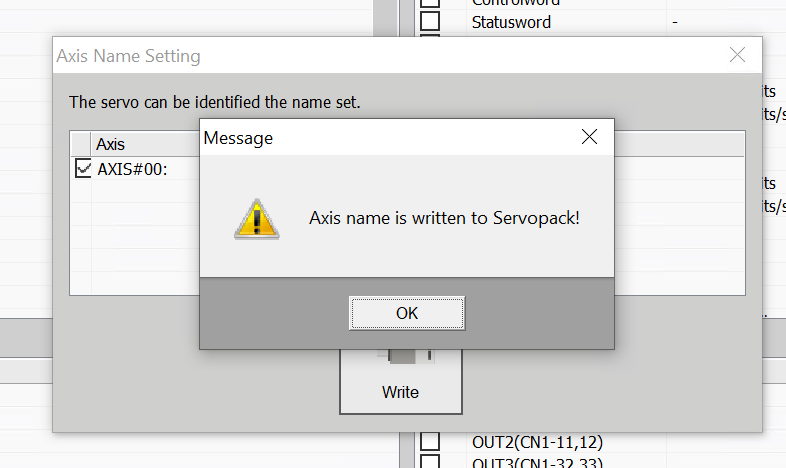

Finally, click the Write button to write the axis name to the servo.

Done!

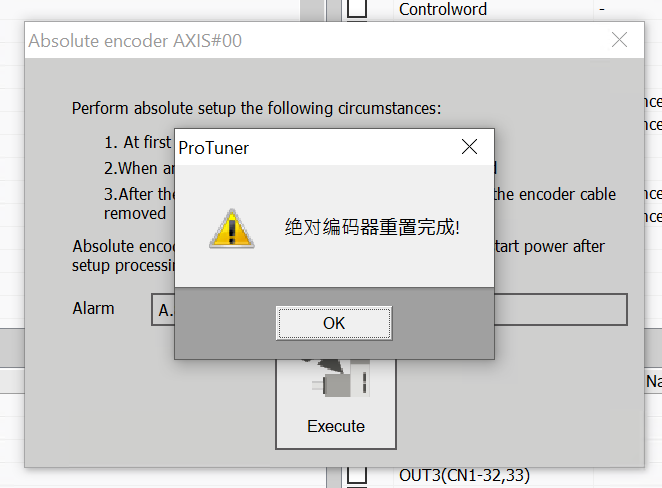

Reset of the Absolute Encoder

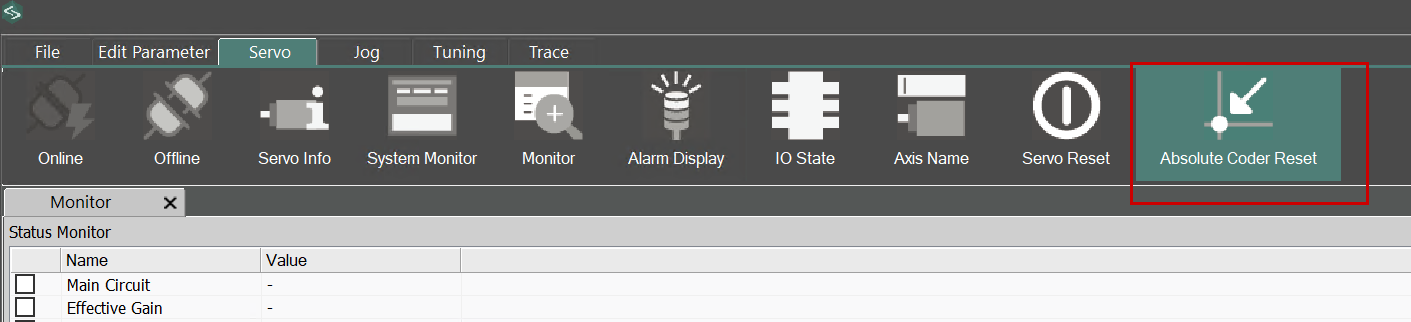

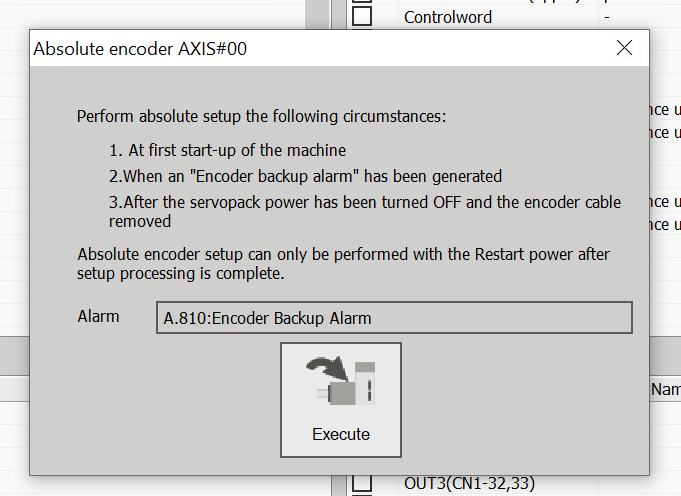

The initial shipment of the SERVO requires an absolute encoder reset operation. Click Servo→Absolute Encoder Reset.

Proceed with Execute.

Next, click the Execute button.

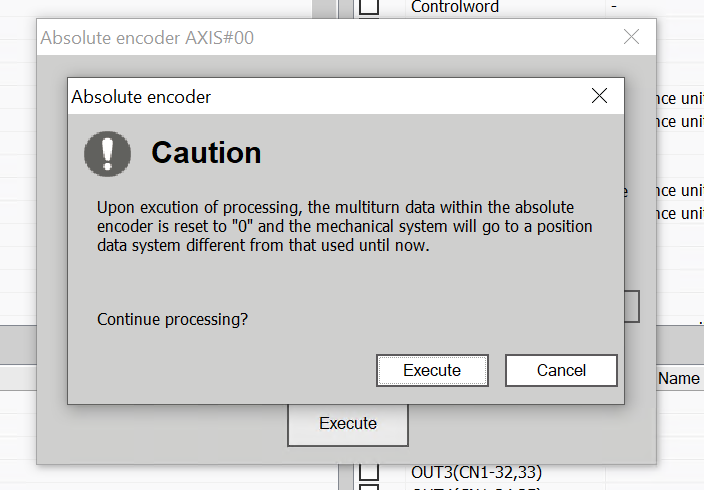

Click Execute again.

Done!(For some reason it’s in Chinese)

After power cycling the servo drive, the A810 error was cleared.

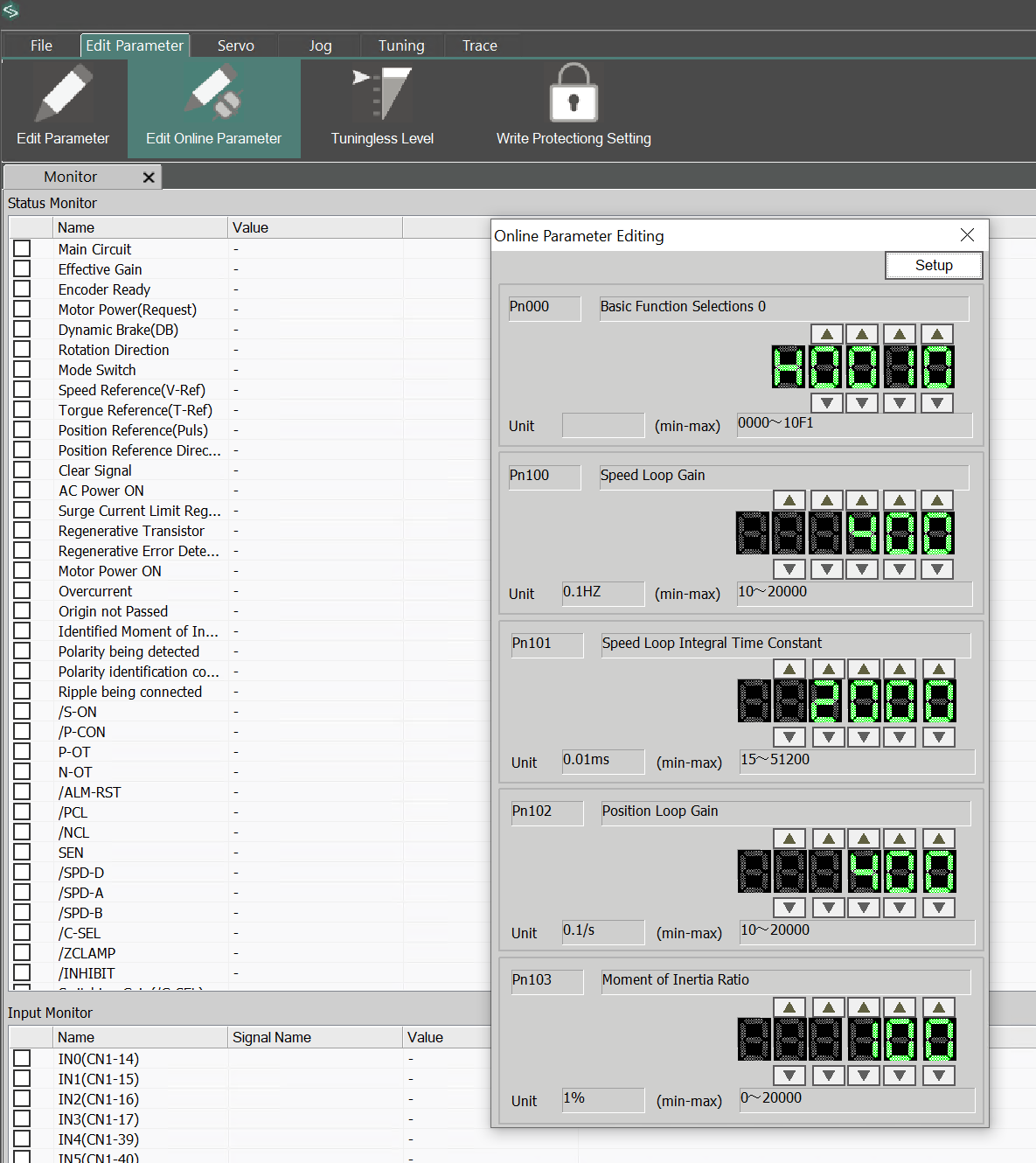

Editing Online Parameters

Click Edit Parameters→Edit Online Parameters to modify certain parameters directly online.

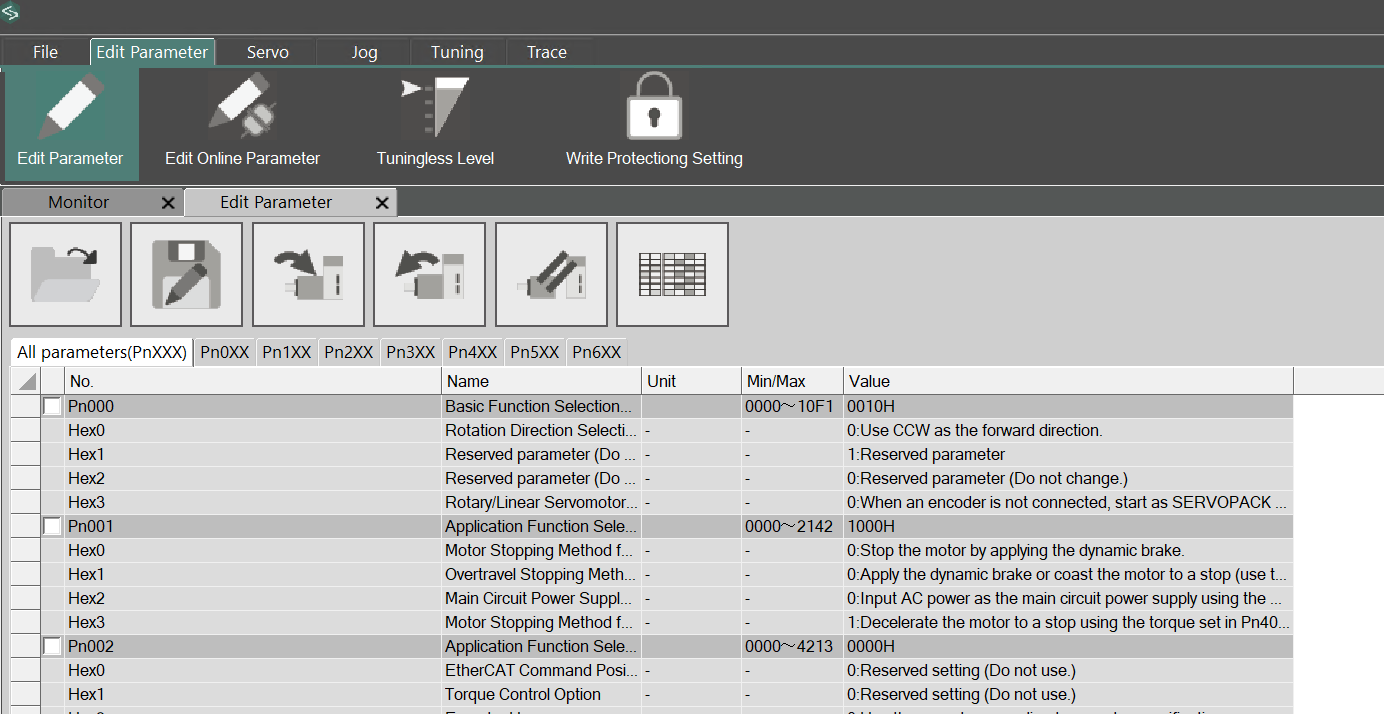

Edit parameters

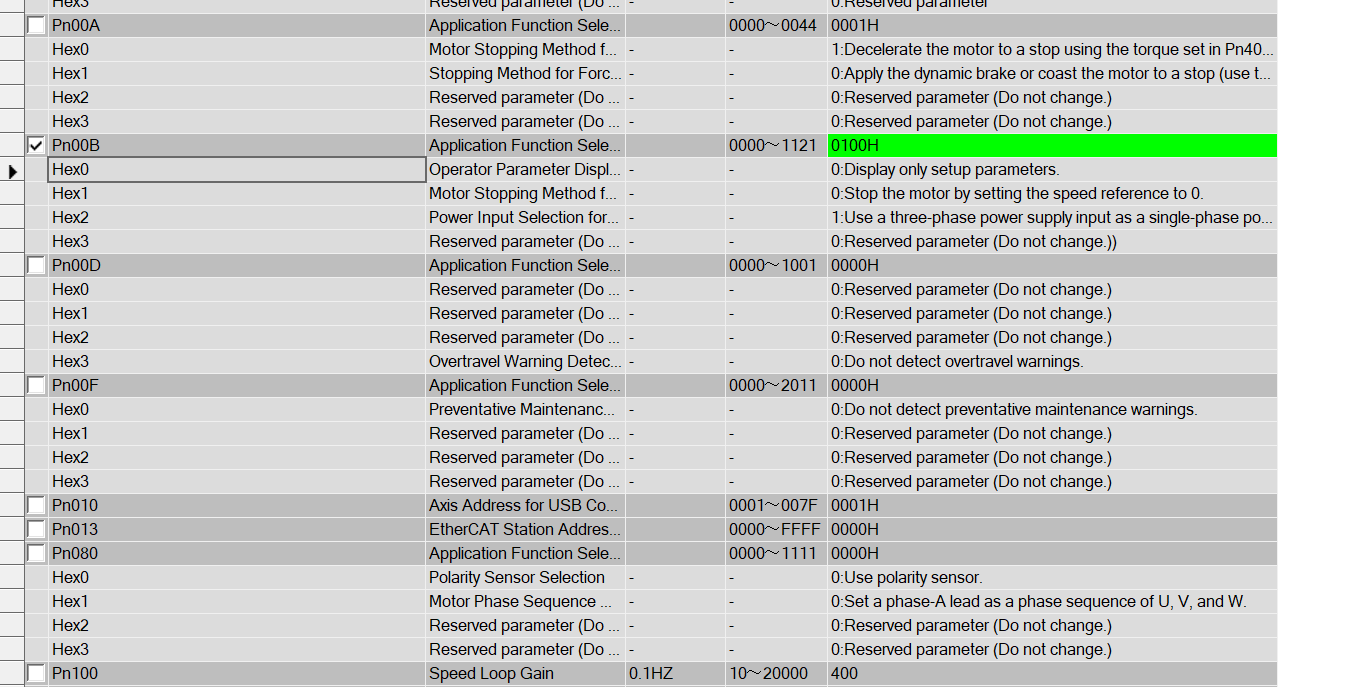

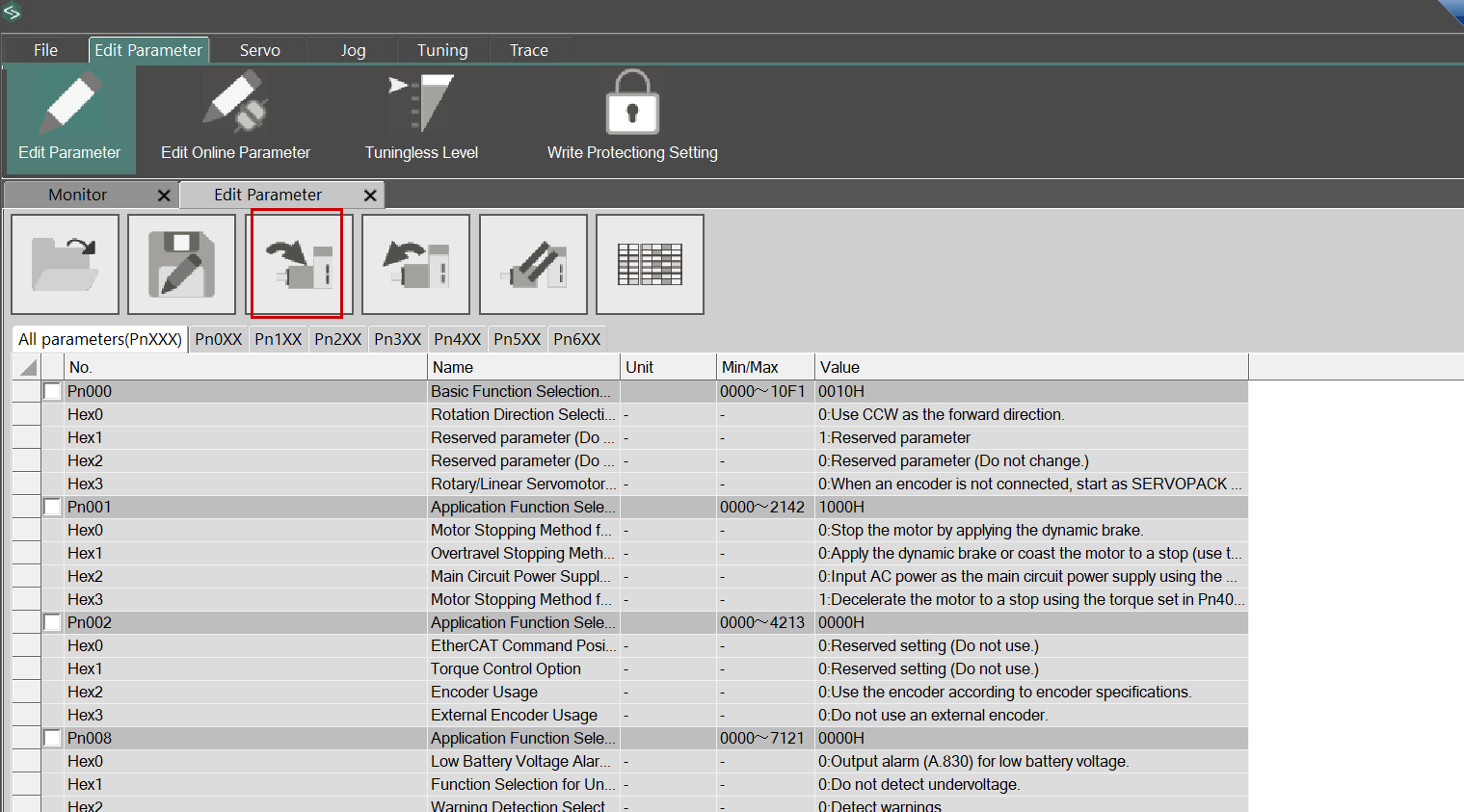

Next, edit the internal parameters offline via Edit Parameters → Edit Parameters.

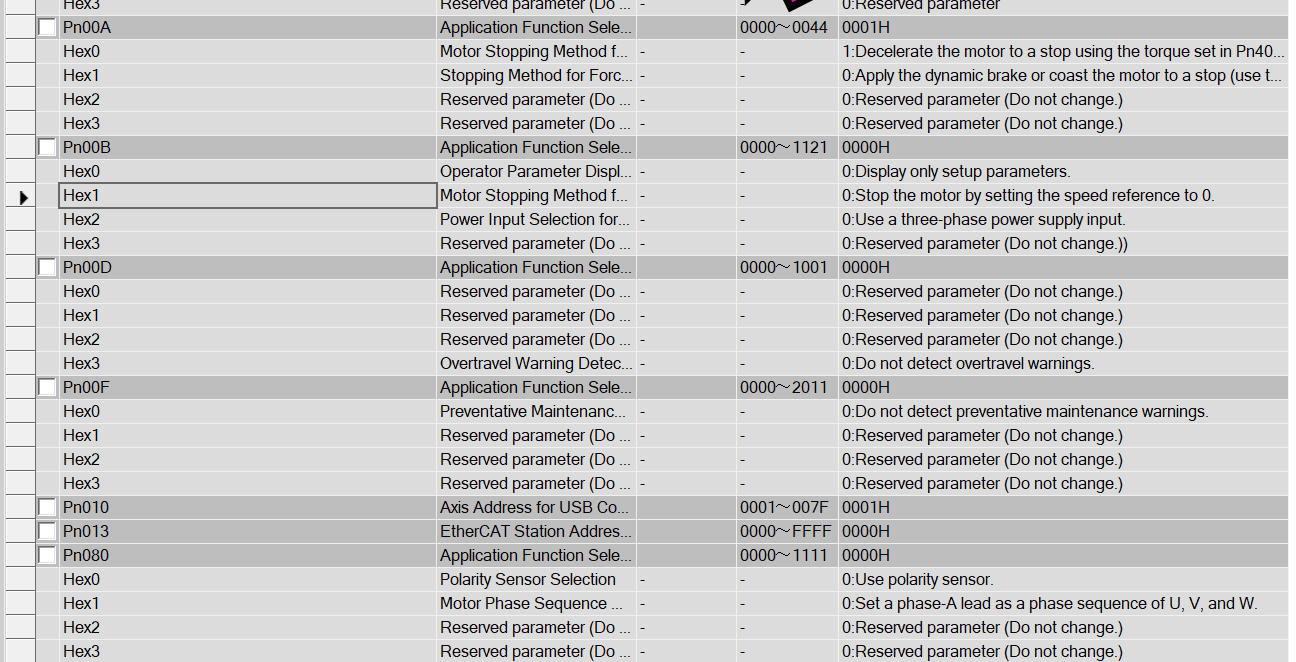

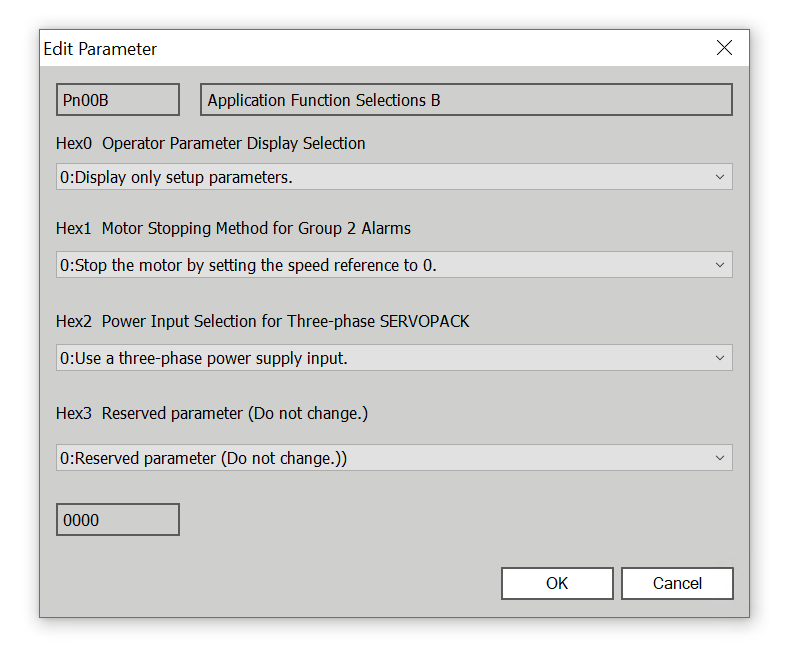

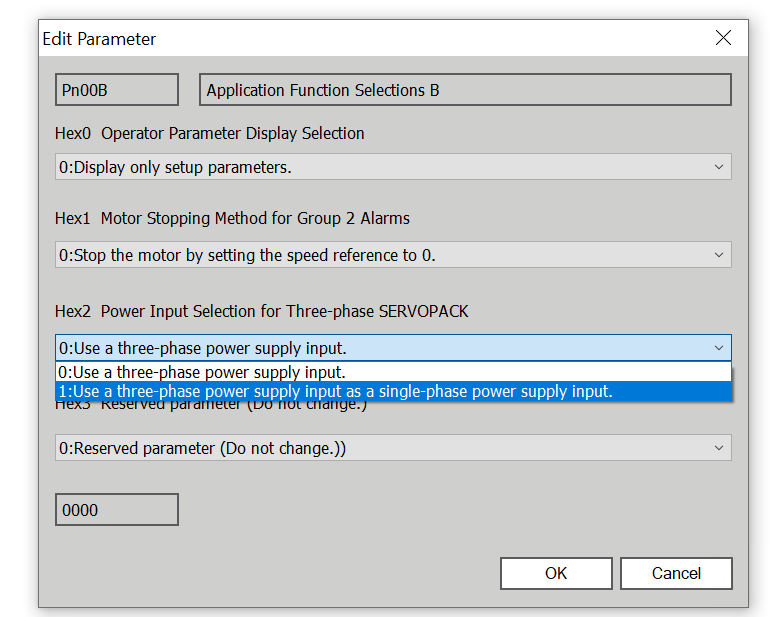

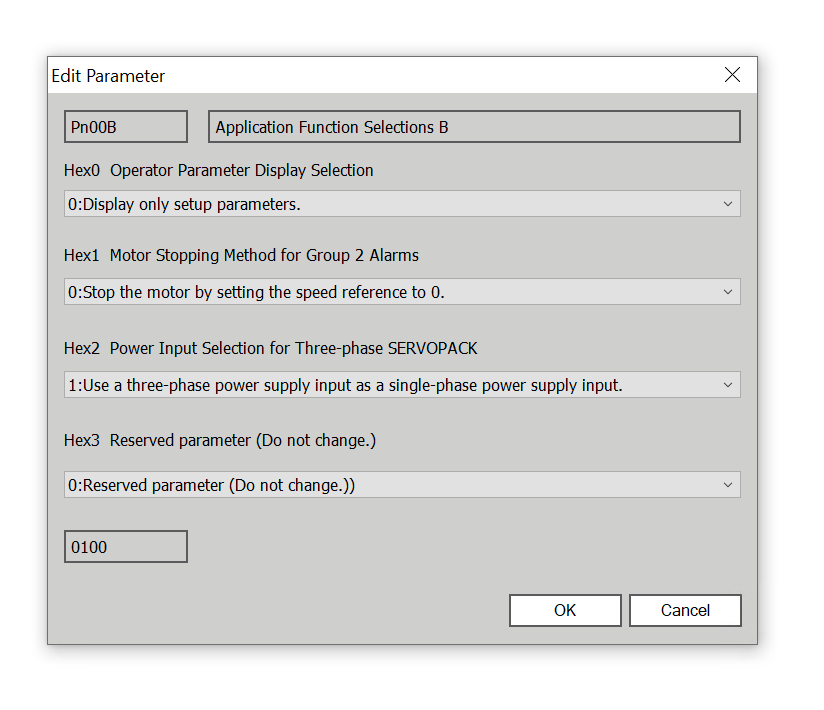

Parameter Pn00B for single-phase power supply enabled

I’m testing the Servo Drive at home, so I only have single-phase power available. Click Pn00B→Hex1.

The parameter editing screen shown below will appear.

Set Hex2 to 1.

Click OK to confirm the parameter changes.

Done!The edited parameter will turn green.

Write parameters

Next, use the button shown below to write the parameters to the SERVO DRIVE.

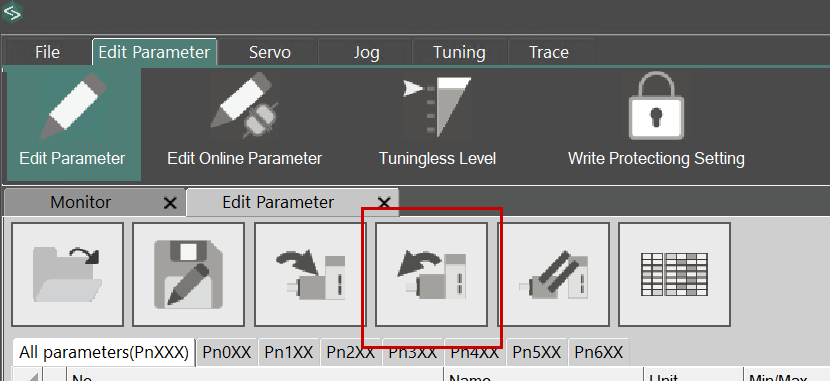

Load parameters

Additionally, you can click the button shown below to read the SERVO parameters.

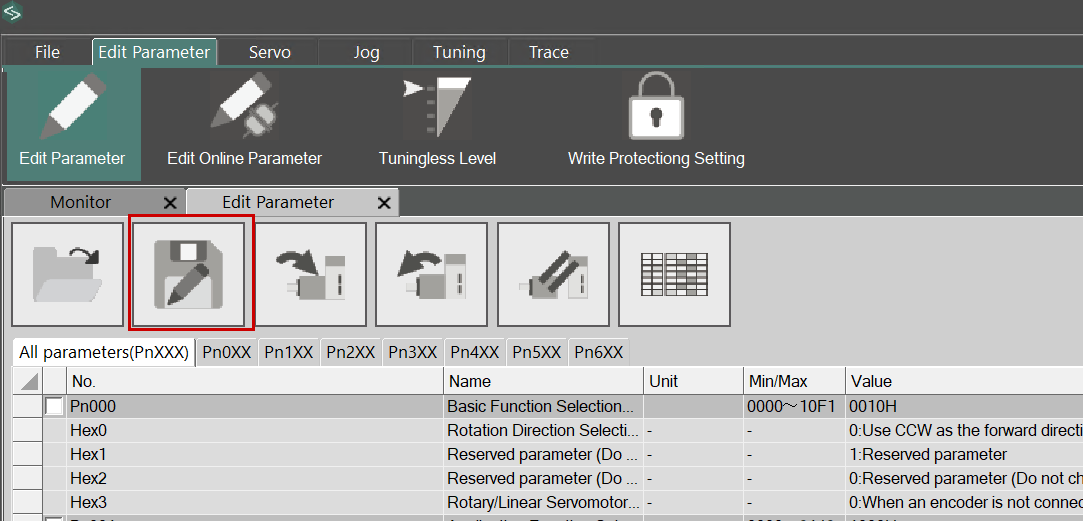

Save

Finally, you can save the parameters as a text file using the button shown below.

Result

Done!After restarting the servo’s power supply, the error was cleared.

Jog operation

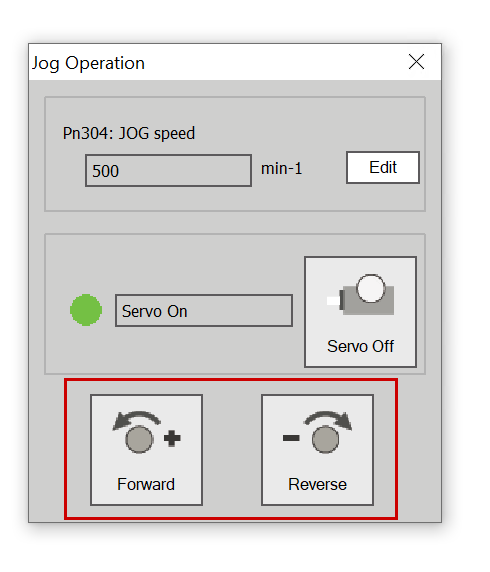

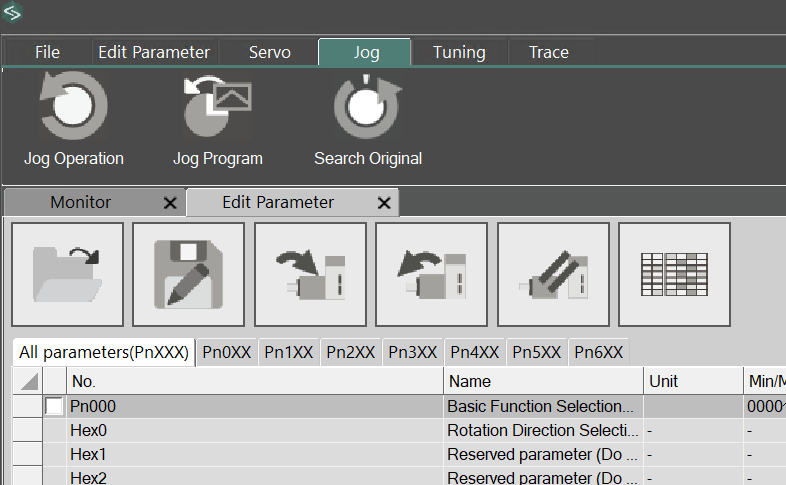

Finally, we’ll introduce the Servo Jog operation from ProTuner. Please Click Jog.

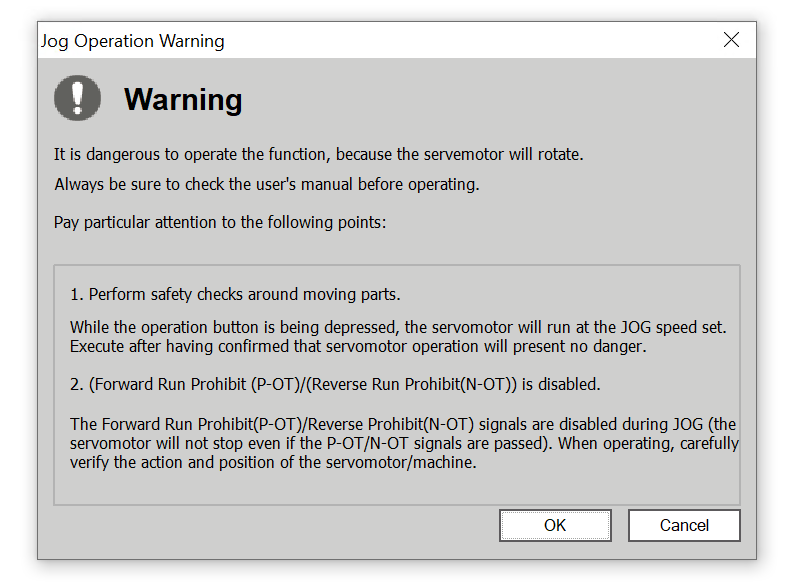

Proceed with OK.

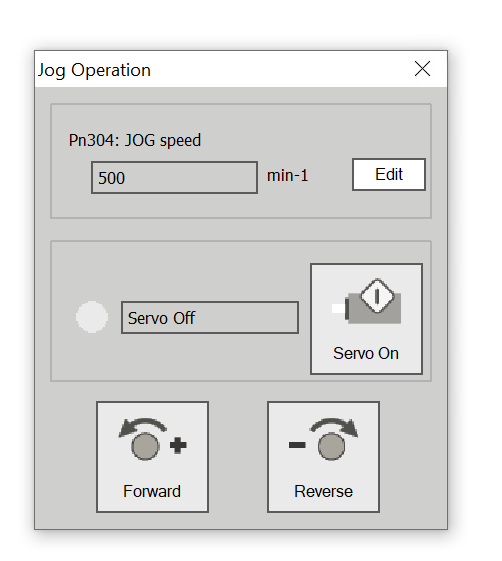

This is the ProTuner jog control screen.

Turn on the servo power with Servo On.

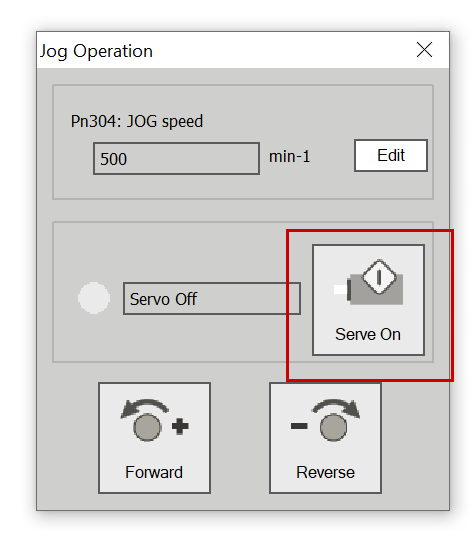

Done!It has changed to Servo On.

Finally, use the button shown below to switch the servo between forward and reverse rotation.