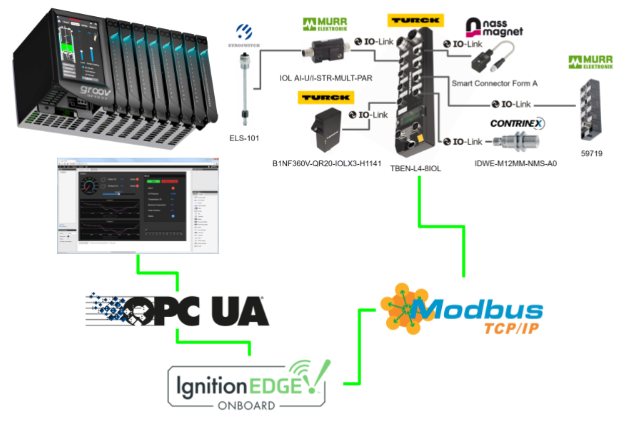

In this article, the Ignition EDGE built into the EPIC PLC is set up to convert the data taken from the TURCK via Modbus into an OPC-UA Server Node, which is then displayed in the Groov View of the EPIC PLC.

Let’s get started.!

Ignition Edge?

Ignition Edge is a tool that allows you to easily capture, process and visualize critical data at the remote edge of your network.

The new Edge product line combines five previous Edge products into two Edge products: the Ignition Edge IIoT and the Ignition Edge Panel.

Ignition Edge IIoT

The Ignition Edge IIoT turns touch panels and client terminals into lightweight, MQTT-enabled edge gateways for remote data collection and more. It is ideal for polling data at the device’s location and publishing the data to an MQTT server that business systems and applications can access.

The driver tags and device connections currently included in Ignition Edge IIoT are unlimited and include the ability to run scripts, create REST APIs, synchronize data to a central server and act as an EAM agent gateway.

Ignition Edge Panel

The Ignition Edge Panel includes all of the Ignition Edge IIoT plus local visualization for the HMI, as well as the Edge Panel visualization system, Perspective (2 sessions) or Vision (1 local client, 1 remote client).

Edge Different from Standard Ignition?

The functionality of the Ignition Edge is more limited than the standard Ignition platform; the Edge does not have database connectivity and 35 days of internal data storage for history and event logging.

GroovEPIC x IgnitionEDGE?

Two Inductive Automation® products are available with groov EPIC and groov RIO MM2 modules: full ignition or Ignition Edge®.

- full Ignition

- Ignition Edge®.

Inductive Automation’s products provide two key connectivity for IIoT applications – OPC UA and MQTT with Sparkplug or string payloads.

Full Ignition also adds external access to OPC UA servers, scripting, database support and a wide range of Ignition modules.

OPC UA

The OPC UA server is available for groov EPIC and groov RIO MM2 Ignition and Ignition Edge. Ignition can also take data from devices such as Allen-Bradley®, Siemens®, Modbus®, Opto 22 groov EPIC, groov RIO and SNAP PAC and convert them as OPC UA Server Tags.

This means that there is no need to buy, configure and maintain separate devices to view and manipulate data from these systems.

The following are currently supported Drivers.

- Allen-Bradley PLCs

- Logix

- SLC

- PLC-5®

- MicroLogix™

- Siemens PLCs:

- S7-300

- S7-400

- S7-1200

- S7-1500

- Modbus/TCP device

- Modbus RTU over TCP

It should be noted that other Drivers need to be purchased separately.

MQTT

MQTT transmission modules are also available for Ignition and Ignition Edge; MQTT (Message Queue Telemetry Transport) is a pub-sub protocol, which is suitable for many IIoT applications due to its configuration.

MQTT in groov EPIC and groov RIO can use either string payloads or the Sparkplug B Payload specification; Spark Plug defines messages that travel over MQTT and that the data from remote devices and applications is up-to-date and valid Verification.

Summary

With both OPC UA and MQTT, data can be exchanged with A-B, Siemens, Modbus and Opto 22 systems in a non-intrusive way, without the need for an industrial PC, additional firewalls or expensive network connections.

Ignition Edge Status

Check from the Groove MANAGE screen whether the EPIC PLC is enabled – by Default, the Ignition Edge is Running and Config is Enable.

Ignition Edge Configuration

The “Open Ignition Edge” button opens the Ignition Edge configuration screen.

This is the Ignition EDGE screen.

Sign in

Initially, click on ‘Sign in to Reset’ to log in to the system.

- Username :admin

- Password :password

Rest Trial

If the login is successful, click ‘Reset Trial’ to reset the Trial time. You can run it for up to two hours at a time without a license, after which the system will stop and you will have to reset it manually again.

Setup the User

Click the CONFIGURE button to configure the User settings.

SECURITY>Users, open the Roles Menu.

This is the User settings screen of Ignition EDGE, where you can add and edit Users according to your application.

OPC UA Server

We have just said that Ignition EDGE can collect data from each device and convert it as an OPC UA Server Node. First, configure the OPC-UA Server settings for Ignition EDGE.

Anonymous Access

In actual operation of the OPC-UA Server, Anonymous Access should be disabled, but since you are only verifying the connection now, please include the Checkbox for Allow Anonymous Access.

Server Port

Server Port can be set to the connection Port of the OPC UA Server, which is 4096 by Default.

Save Changes

Finally, click ‘Save Changes’ to apply the settings.

Devices Configuration

The next step is to configure the communication settings for the devices you want to collect Ignition EDGE from, Ignition EDGE can convert the data collected from Devices into OPC UA Server Nodes, where “Devices” are the PLCs and EDGE devices you want to collect. The “Devices” can be PLCs, EDGE devices, etc. that you want to collect.

To configure Devices, open OPC-UA SERVER>Devices.

Create new Device

The Devices configuration screen appears and click ‘Create new Devices’.

Protocol

The screen changes to a Protocol selection screen, this time set to Modbus TCP and press Next> to proceed.

Ports

Set the Port of the Modbus TCP Server. In this case we are collecting IO-Link Master data on the TURCK, the Modbus TCP Server on the TURCK device is Port 502.

Name・HostIP

Next, enter the name of the Modbus TCP Server in Name, set the Host Name to the IP address of the Modbus TCP Server and finally click the “Create New Devices” button.

Status

Done!New Devices are added and the Status changes to “Connected”. This means that the Ignition EDGE and the Modbus TCP Server are communicating.

Address

From the More Menu, there is an Addresses item where you can set the registers you want to access within the Modbus TCP Server.

Add new Access

This is the Address Configuration screen.” Add Row” to add a new access.

One Row has been added.

Prefix

The Prefix is the prefix setting for that Address name.

Start

Start is the start number of the register you want to access in this Row.

End

End is the last number of the register accessing this Row.

Unit ID

Unit IDはModbus TCP ServerのIDになります。

Modbus Type

Modbus Type is the type of Modbus register accessed by this Row.

Modbus Address

The Modbus Address is the register number to be accessed by this Row.

Result

Done!When the communication settings are saved in the Save button, the Status shows Connected, i.e. communication is OK.

Groov View Configuration

The next step is to add data accessed via Ignition EDGE from Groov View.

Add OPC UA Server Access

Add New Devices>OPC UA Server.

The configuration screen of the OPC UA Server connected to the Groov View is displayed.

Name

Enter the name of the Tag to be connected in the Name field.

Sever URL

This is the End Point of the OPC UA Server. In this article, we will connect to the Local OPC-UA Server of Ignition EDGE, so enter 127.0.0.1:4096.

Under the Server URL field there is a small “2” button.

Click on the preceding button to display the OPC UA Server connection guide.

Test Connection

Finally, click on “Test Connection” to check the connection between the EPC PLC and the OPC-UA Server.

Done!

Add Tags

Finally, the Tag should be displayed in the Groov View.

The connection status of the OPC-UA Server can also be added to the screen from the Folder in Diagnostics with the required Tag (e.g. connection status, Port number, etc.).

Done!

Result

Groov View was able to acquire and display Turck’s IO-Link Master data via OPC-UA on the Ignition EDGE.