Hallo and In the last tutorial I showed how to use TF5430 with RoboDK to simulate a Xplanar with the free movement operation.In this part, I will configure the system with Tracks and Add a Robot in our station.

Hope you like this!

Reference Link

Track?

Track is a user-defined path in your Xplanar project to allow these movers to move on this track( it can be line, circle), but also we can connect and join the mover in multiple tracks in the system.

Although we will not have a deep discussion of collision in this time,collision is avoided with multiple movers to make sure the distances between movers are not too close.

API

In this Part I will only explain the DUT and Function Block that used in this tutorial.

DUT

ST_JoinTrackOptions

The Option of JoinTrack command.

| Name | Type | Default | Description |

| useOrientation | BOOL | True | the target orientation is also reachedat the end of themovement |

ST_LeaveTrackOptions

The Option of LeaveTrack command.

| Name | Type | Default | Description |

| useOrientation | BOOL | True | the target orientation is also reachedat the end of themovement |

ST_MoveOnTrackOptions

MoveOnTrackコマンドのオプションです。

| Name | Type | Default | Description |

| gap | LREAL | 200.0 | Track上のMover間の最小距離 |

| direction | MC_DIRECTION | MC_DIRECTION.mcDirectionNonModulo | Mover移動するの方向 |

| additionalTurns | UDINT | 0 | |

| moduloTolerance | LREAL | 0.0 |

MC_PlanarMover

In the last tutorial PlanarMover object is explained, and I will show you the method for Track operation in here.This Function Block can not be directly called in the user program and please use the method of its instance.

JoinTrack

Join the mover to specific track and the mover can follow the track to move.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

| constraint | IPlcDynamicConstraint | The constraint of Planar |

| options | ST_JoinTrackOptions | The moving Option |

VAR_INOUT

| Name | Type | Description |

| targetTrack | MC_PlanarTrack | The Track that mover would like to join |

LeaveTrack

operate the mover to leave the track and we can specify the position while the mover is left from Track.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

| constraint | IPlcDynamicConstraint | The constraint of Planar |

| options | ST_LeaveTrackOptions | The moving Option |

VAR_INOUT

| Name | Type | Description |

| targetPosition | PositionXYC | The Target position |

MoveOnTrack

operate the mover to follow the track to create a movement.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

| targetTrack | MC_PlanarTrack | Target track for the movement. If none is specified, this defaultsto the current track. |

| targetPositionOnTrack | LREAL | Target position on the target track |

| constraint | IPlcDynamicConstraint | The constraint of Planar |

| options | ST_MoveOnTrackOptions | The moving Option |

Enable

Enable the Planar Mover.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

Update

This method must be triggered each cycle,to update the internal state of the object.

MC_PlanarTrack

Planar Movers object can follow the Track object to perform the movement and Planar Movers on the track automatically avoid collisions with each other.This Function Block can not be directly called in the user program and please use the method of its instance.

AppendLine

Append a line in the Planar Track.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

VAR_INOUT

| Name | Type | Description |

| start | PositionXYC | The start position of Line |

| end | PositionXYC | The end position of Line |

StartFromTrack

Sets the other Planar Tracks endpoint as the start point of this Planar Track.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

VAR_INOUT

| Name | Type | Description |

| track | MC_PlanarTrack | The target Track |

EndAtTrack

Appends a smooth transition from the end of this Planar Track to the other Planar Tracks start point.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

VAR_INOUT

| Name | Type | Description |

| track | MC_PlanarTrack | Planar Track Object |

Enable

Enable the Planar Mover.

VAR_INPUT

| Name | Type | Description |

| commandFeedback | MC_PlanarFeedback | The Feedback of the command |

Update

Enable the Planar Mover.

AddTrack

Adds a track to the TrackTrail. The track should start at the end of the currently last track.

| Name | Type | Description |

| track | MC_PlanarTrack | The tagert track that you would like to add |

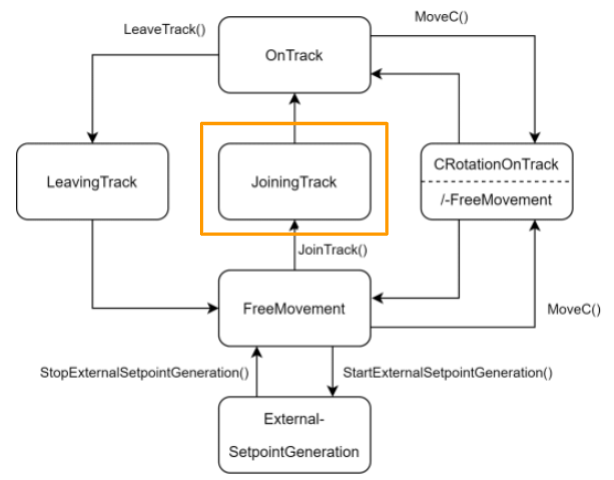

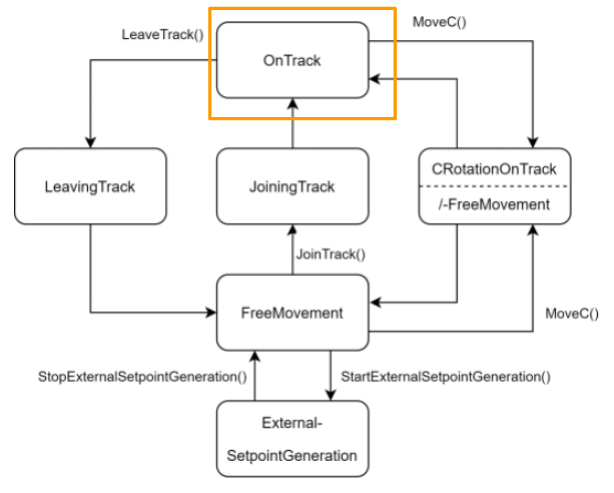

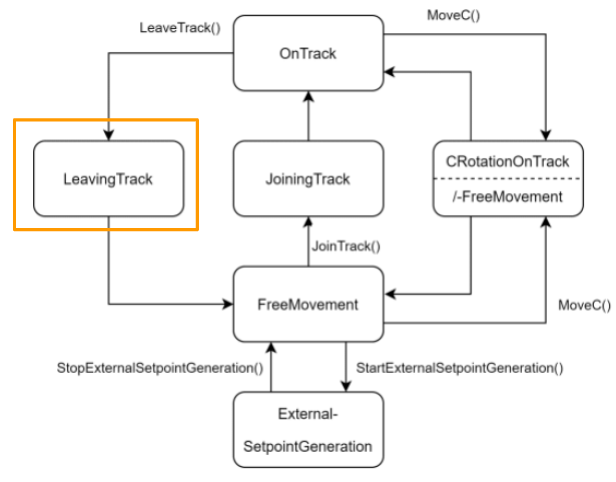

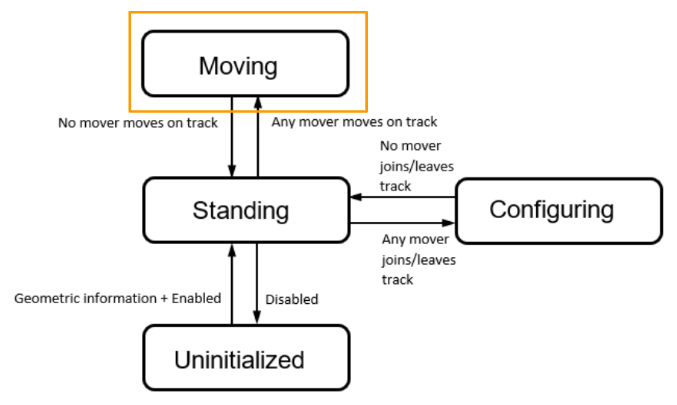

Planar mover command diagram

As I mentioned before in the last tutorial,there are 6 types of commands in Planar Mover.

- OnTrack

- LeavingTrack

- JoiningTrack

- ExternalSetpointGeneration

- CRotationFreeMovement/-

- FreeMovement

JoiningTrack

In JoiningTrack Mode, mover will not receive and execute any command, and the Mover will shift the status to OnTrack after the JoinTrack command is finished.

OnTrack

The mover will be in OnTrack Mode after the JoinTrack command is finished.

In OnTrack mode, MoveOnTrack Command can be received to execute an on track movement, or leave the Track by using LeaveTrack Command.

And also, the mover will shift to CRotationOnTrack mode while a moveC command is received.

LeavingTrack

In the LeavingTrack mode the mover will not receive any command and it will shift to FreeMovement mode after LeaveTrack command is Finished.

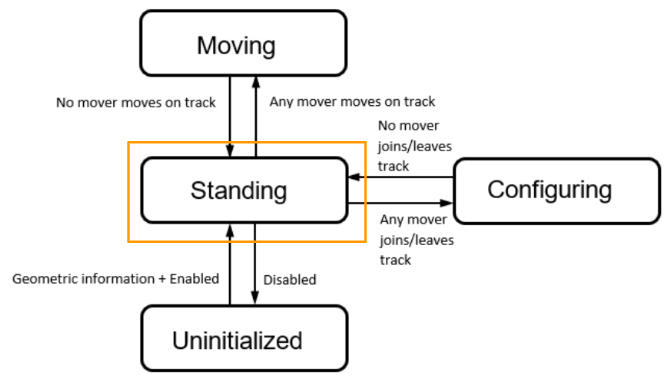

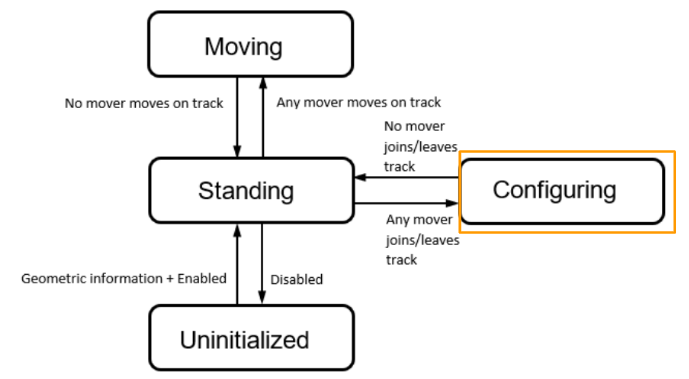

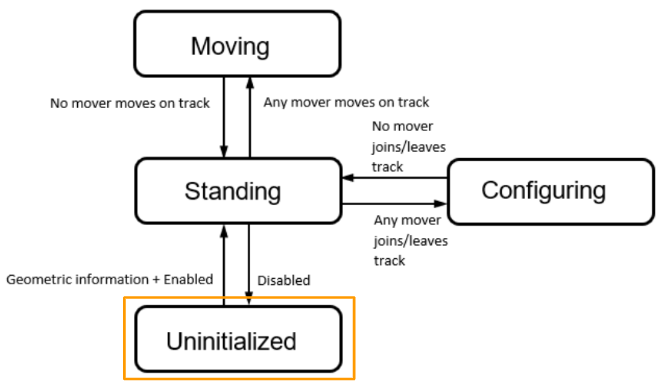

Planar track operation modes

There are 4 modes in the Planar Track to show the track status.

- Moving

- Standing

- Configuring

- Uninitialized.

Moving

In the Moving Mode, It means that movers are moving on the track, and the Track status will shift from standing mode to moving mode. After the movement is finished, the track status will shift back to Standing mode automatically.

The mover can not execute the commands like JoinTrack/LeaveTrack while in Moving Mode.

Standing

In Standing Mode the mover can use the Travel command like JoinTrack/LeaveTrack/MoveOnTrack.

Configuring

In the Configuring mode, it means that at least one Mover is executing the LeaveTrack Command or JoinTrack Command to affect the Track object. The status will shift to Configuring while the first mover is joining/leaving the Track, and Shift to Standing mode while all movers ‘ commands are finished.

Uninitialized

In the uninitiated mode the movers can not be used – The reason may be geometric is not configured and the user should set up all geometric information before Track is enabled, and the track will shift to Standing mode automatically.

Basic Setup

We will start to set up the hardware configuration first.

Add Planar Object

Go to Motion>your mc project >Axes>Groups Right Click and Add New Item.

Choose Planar Track and OK.

Planar Track group is created.

Click the Track object and we can set up the parameter for the Track.

ANd then Go to Group1>McToPlc>STD >Right Click and Change Link.

Choose the TRACK object that is inside your user-program.

Add One More Mover

insert one more Mover inside your MC Project.

Set Mover Init Position

The initial position of Movers can be configured here. Click the Mover1.

Go to the Parameter(init) tab and set the Initial position as 0 in x,y,z,a,b,c.

次はMover2です。

Go to the Parameter(init) tab and set the Initial position as 240in x and 0 in y,z,a,b,c.

Implementation-1

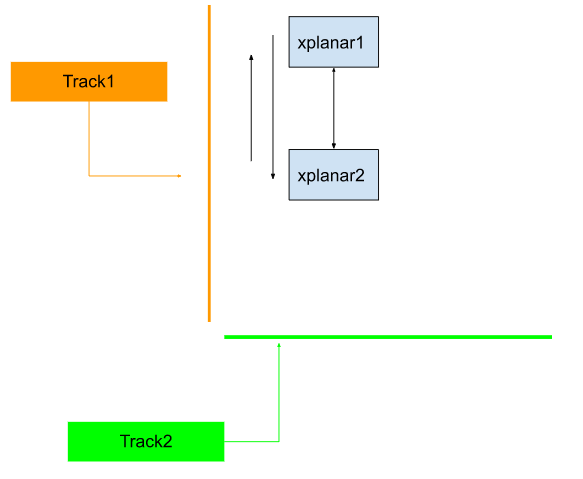

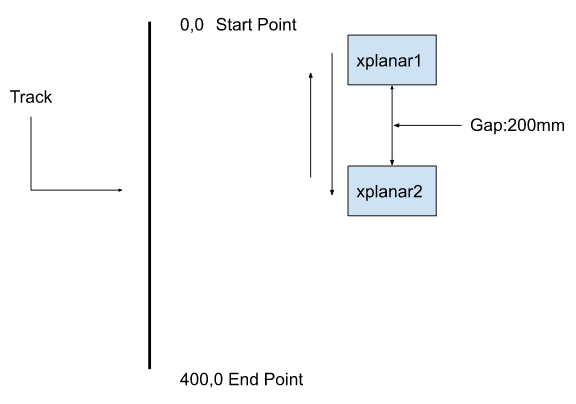

We will set the first Implementation that only has Track 1 as Start point=0.0 and End Point as 400,0.The Xplanar1 and Xplanar2 will move based on the Track1.

GVL

| {attribute ‘qualified_only’} VAR_GLOBAL mover:MC_PlanarMover; mover2:MC_PlanarMover; tracks : ARRAY[1..5]OF MC_PlanarTrack; commandFeedback:MC_PlanarFeedback; commandFeedbacks:ARRAY[0..4]OF MC_PlanarFeedback; END_VAR |

Code

VAR

| PROGRAM MAIN_TrackExample1 VAR //Track Options MoveOnTrackOption:ST_MoveOnTrackOptions; //Control Variables iStep : UDINT; //Position Setpoint pos1, pos2 : PositionXYC; MoveOnTrackPosition1:REAL:=150; MoveOnTrackPosition2:REAL:=350; END_VAR VAR CONSTANT cStepInit :UDINT := 0; cStepCheckTrackerEnabled :UDINT := 10; cStepEnableMovers :UDINT := 20; cStepCheckMoversEnabled :UDINT := 30; cStepJoinTrack :UDINT := 40; cStepCheckOnTrack :UDINT := 50; cStepMoveOnTrack :UDINT := 60; cStepCheckPosition :UDINT := 70; cStepEnd :UDINT := 80; END_VAR |

PROGRAM

We will Initiate the Track>Set the start point and end point of the Track>Enable the Track>Enable the movers>operate the movement.

| //Sending Data to RoboDK by OPCUA GVL2RoboDK.xplanar1.pos.ActPos:=GVL.mover.MCTOPLC.ACT.ActPos; GVL2RoboDK.xplanar2.pos.ActPos:=GVL.mover2.MCTOPLC.ACT.ActPos; //Gap Setting between the mover MoveOnTrackOption.gap:=200.0; CASE iStep OF cStepInit: pos1.SetValuesXY(x:=0,y:=0); pos2.SetValuesXY(x:=400,y:=0); GVL.tracks[1].AppendLine( commandFeedback:=GVL.commandFeedbacks[0] ,start:=pos1 ,end:=pos2 ); GVL.tracks[1].Enable(commandFeedback:=GVL.commandFeedbacks[1]); iStep :=cStepCheckTrackerEnabled; cStepCheckTrackerEnabled: IF GVL.tracks[1].MCTOPLC_STD.State = MC_PLANAR_STATE.Enabled THEN iStep := cStepEnableMovers; END_IF cStepEnableMovers: GVL.mover.Enable(commandFeedback:=GVL.commandFeedbacks[0]); GVL.mover2.Enable(commandFeedback:=GVL.commandFeedbacks[1]); iStep := cStepCheckMoversEnabled; cStepCheckMoversEnabled: IF GVL.mover.MCTOPLC.STD.State = MC_PLANAR_STATE.Enabled AND GVL.mover2.MCTOPLC.STD.State = MC_PLANAR_STATE.Enabled THEN iStep := cStepJoinTrack; END_IF cStepJoinTrack: GVL.mover.JoinTrack( commandFeedback:=GVL.commandFeedbacks[0] ,targetTrack:=GVL.tracks[1] ,constraint:=0 ,options:=0 ); GVL.mover2.JoinTrack( commandFeedback:=GVL.commandFeedbacks[0] ,targetTrack:=GVL.tracks[1] ,constraint:=0 ,options:=0 ); iStep := cStepCheckOnTrack; cStepCheckOnTrack: IF GVL.mover.MCTOPLC.STD.CommandMode = MC_PLANAR_MOVER_COMMAND_MODE.OnTrack AND GVL.mover2.MCTOPLC.STD.CommandMode=MC_PLANAR_MOVER_COMMAND_MODE.OnTrack THEN iStep := cStepMoveOnTrack; END_IF cStepMoveOnTrack: GVL.mover.MoveOnTrack( commandFeedback:=GVL.commandFeedbacks[0] ,targetTrack:=GVL.tracks[1] ,targetPositionOnTrack:=MoveOnTrackPosition1 ,constraint:=0 ,options:=MoveOnTrackOption ); GVL.mover2.MoveOnTrack( commandFeedback:=GVL.commandFeedbacks[0] ,targetTrack:=GVL.tracks[1] ,targetPositionOnTrack:=MoveOnTrackPosition2 ,constraint:=0 ,options:=MoveOnTrackOption ); iStep := cStepCheckPosition; cStepCheckPosition: IF GVL.mover.MCTOPLC.SETONTRACK.SetPos >= MoveOnTrackPosition1-0.1 AND GVL.mover2.MCTOPLC.SETONTRACK.SetPos >= MoveOnTrackPosition2-0.1 THEN iStep := cStepEnd; END_IF cStepEnd: END_CASE //Update GVL.mover.Update(); GVL.mover2.Update(); GVL.tracks[1].Update(); |

Result

Implementation-2

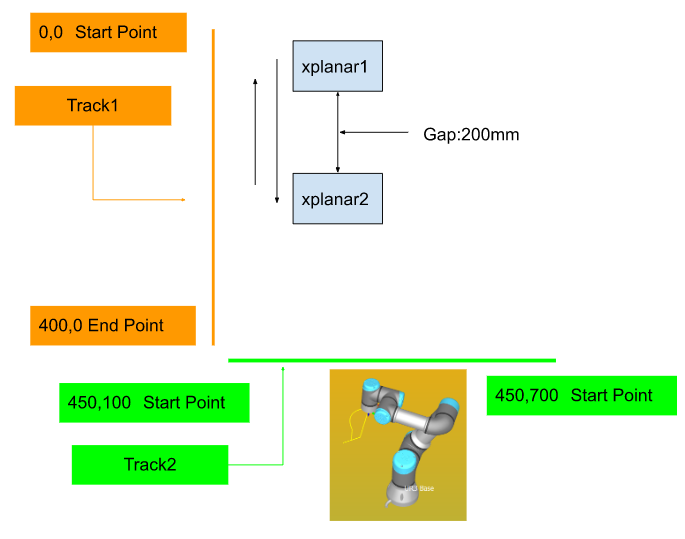

In the second Implementation we have 2 Tracks, mover1 and mover2 will follow the Track1 to perform the movement to the end of End point in Point1, and joint Track2 and Stop the movers in front of the Robot>Perform the Pick up Program of Robot> Go Back.

Reference Link

http://soup01.com/en/category/robot/robodk-en/

RoboDK

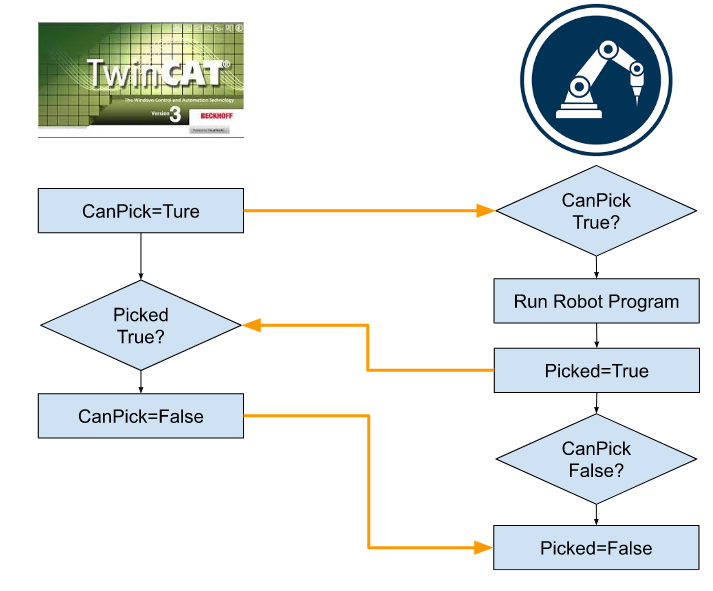

In the Second Implementation a Robot is inserted in out station , and a simple hardshark flow is used in the below.TwinCAT3 will pass a CanPick=True signal to RoboDK side, and RoboDK will execute the Robot Program.

A Picked=True Signal is sent back to TwinCAT3 while the Robot Program is finished, and TwinCAT3 will Turn off the CanPick to False, Finally RoboDK Side will also turn off the Picked signal to false.

Configuration

As with the last tutorial, we will add a new plate and rename these 2 plates as xplanar1 and xplanar2.

And then insert the robot.

Create a simple Robot Program.

Python

In the Python script, the Flow is inserted inside.

| from robodk import robolink # RoboDK API from robodk import robomath # Robot toolbox from opcua import Client,ua RDK = robolink.Robolink() import time from robodk import * # RoboDK API from robolink import * # Robot toolbox def SetNodeValue(Node,value): DataType=Node.get_data_type_as_variant_type() DataValue=ua.DataValue(ua.Variant(value,DataType)) Node.set_data_value(DataValue) XPLANAR=’xplanar1′ XPLANAR2=’xplanar2′ UR3=’UR3′ ENDPOINT=”opc.tcp://DESKTOP-7FE1JP2:4840″ client=Client(ENDPOINT) NODES=’ns=4;s=GVL2RoboDK.xplanar1.pos.ActPos’ NODES2=’ns=4;s=GVL2RoboDK.xplanar2.pos.ActPos’ NODESUR_PICKED=’ns=4;s=GVL2RoboDK.Picked’ NODESUR_CANPICK=’ns=4;s=GVL2RoboDK.canPick’ PROG=’Prog2′ # Program example: xplanar = RDK.Item(XPLANAR) xplanar2 = RDK.Item(XPLANAR2) ur3=RDK.Item(UR3) robotprog=RDK.Item(PROG) if xplanar.Valid() and xplanar2.Valid() and ur3.Valid() and robotprog.Valid(): print(‘Item selected..’) client.connect() print(‘Connected to OPCUA server..’) NodeFromServer=client.get_node(NODES) NodeFromServer2=client.get_node(NODES2) NodeCanPick=client.get_node(NODESUR_CANPICK) NodePicked=client.get_node(NODESUR_PICKED) client.load_type_definitions() _busy=False; # while True: Actpos=NodeFromServer.get_value() CanPick=NodeCanPick.get_value() # CurrentPos=xyzrpw_2_pose([Actpos.x,Actpos.y,Actpos.z,Actpos.a,Actpos.b,Actpos.c]) xplanar.setPoseAbs(CurrentPos) #print(Actpos.x,Actpos.y,Actpos.z,Actpos.a,Actpos.b,Actpos.c) Actpos=NodeFromServer2.get_value() # CurrentPos=xyzrpw_2_pose([Actpos.x,Actpos.y,Actpos.z,Actpos.a,Actpos.b,Actpos.c]) xplanar2.setPoseAbs(CurrentPos) if not _busy and CanPick: value=robotprog.RunProgram() _busy=True if not robotprog.Busy() and _busy: SetNodeValue(NodePicked,True) _busy=False if not CanPick: SetNodeValue(NodePicked,False) print(_busy) print(‘CanPick=’,CanPick) #time.sleep(0.1) client.disconnect() |

TwinCAT3 Side

Now we can configure the TwinCAT3 Side.

Confugaraton

In this Implementation we have 2 tracks, please add one more Planar Track inside your MC Project.

And Link it into your user program.

Code

VAR

| PROGRAM MAIN_TrackExample2 VAR state : UDINT; pos1, pos2 : PositionXYC; MoveOnTrackOption:ST_MoveOnTrackOptions; MoveOnTrackOption2:ST_MoveOnTrackOptions; pos3:PositionXYC; postReset:BOOL; TON:TON; END_VAR VAR CONSTANT cStepInit :UDINT := 0; cStepCheckTrackerEnabled :UDINT := 10; cStepEnableMovers :UDINT := 20; cStepCheckMoversEnabled :UDINT := 30; cStepJoinTrack :UDINT := 40; cStepCheckOnTrack :UDINT := 50; cStepMoveOnTrack :UDINT := 60; cStepCheckPosition :UDINT := 70; cStepMover2JoinTrack2 :UDINT := 80; cStepCheckOnTrack2 :UDINT := 90; cStepMover2MoveOnTrack2 :UDINT := 100; cStepRobotCanPickMover2 :UDINT := 110; cStepWaitRobotDoneMover2 :UDINT := 120; cStepMover2MoveBack :UDINT := 130; cStepMover1JoinTrack2 :UDINT := 140; cStepMover1MoveOnTrack2 :UDINT := 150; cStepRobotCanPickMover1 :UDINT := 160; cStepWaitRobotDoneMover1 :UDINT := 170; cStepMover1MoveBack :UDINT := 180; cStepEnd :UDINT := 999; END_VAR |

PROGRAM

| //Sending Data to RoboDK by OPCUA GVL2RoboDK.xplanar1.pos.ActPos:=GVL.mover.MCTOPLC.ACT.ActPos; GVL2RoboDK.xplanar2.pos.ActPos:=GVL.mover2.MCTOPLC.ACT.ActPos; // MoveOnTrackOption.gap:=200.0; MoveOnTrackOption.direction:=1; CASE state OF cStepInit: pos1.SetValuesXY(x:=0,y:=0); pos2.SetValuesXY(x:=400,y:=0); GVL.tracks[1].AppendLine(commandFeedback:=GVL.commandFeedbacks[0],start:=pos1,end:=pos2); pos1.SetValuesXY(x:=450,y:=100); pos2.SetValuesXY(x:=450,y:=700); GVL.tracks[2].StartFromTrack(0,track:=GVL.tracks[1]); GVL.tracks[2].AppendLine(commandFeedback:=GVL.commandFeedbacks[2],start:=pos1,end:=pos2); GVL.tracks[2].EndAtTrack(0,track:=GVL.tracks[1]); pos3.x:=200; pos3.y:=0; GVL.mover2.SetPosition(0,pos3); state := cStepCheckTrackerEnabled; cStepCheckTrackerEnabled: GVL.tracks[1].Enable(commandFeedback:=GVL.commandFeedbacks[1]); GVL.tracks[2].Enable(commandFeedback:=GVL.commandFeedbacks[3]); IF GVL.tracks[1].MCTOPLC_STD.State = MC_PLANAR_STATE.Enabled AND GVL.tracks[2].MCTOPLC_STD.State = MC_PLANAR_STATE.Enabled THEN state := cStepEnableMovers; END_IF cStepEnableMovers: GVL.mover.Enable(commandFeedback:=GVL.commandFeedbacks[0]); GVL.mover2.Enable(commandFeedback:=GVL.commandFeedbacks[1]); state := cStepCheckMoversEnabled; cStepCheckMoversEnabled: IF GVL.mover.MCTOPLC.STD.State = MC_PLANAR_STATE.Enabled AND GVL.mover2.MCTOPLC.STD.State = MC_PLANAR_STATE.Enabled THEN state := cStepJoinTrack; END_IF cStepJoinTrack: GVL.mover.JoinTrack(0, GVL.tracks[1], 0, 0); GVL.mover2.JoinTrack(0, GVL.tracks[1], 0, 0); state := cStepCheckOnTrack; cStepCheckOnTrack: IF GVL.mover.MCTOPLC.STD.CommandMode = MC_PLANAR_MOVER_COMMAND_MODE.OnTrack AND GVL.mover2.MCTOPLC.STD.CommandMode=MC_PLANAR_MOVER_COMMAND_MODE.OnTrack THEN state := cStepMoveOnTrack; END_IF cStepMoveOnTrack: GVL.mover.MoveOnTrack( commandFeedback:=GVL.commandFeedbacks[0] ,targetTrack:=GVL.tracks[1] ,targetPositionOnTrack:=150.0,constraint:=0 ,options:=MoveOnTrackOption ); GVL.mover2.MoveOnTrack( commandFeedback:=GVL.commandFeedbacks[0] ,targetTrack:=GVL.tracks[1] ,targetPositionOnTrack:=350.0 ,constraint:=0 ,options:=MoveOnTrackOption ); state := cStepCheckPosition; cStepCheckPosition: IF GVL.mover.MCTOPLC.SETONTRACK.SetPos >= 149.9 AND GVL.mover2.MCTOPLC.SETONTRACK.SetPos >= 349.9 THEN state:=cStepMover2JoinTrack2; END_IF cStepMover2JoinTrack2: GVL.mover2.JoinTrack(0, GVL.tracks[2], 0, 0); state := cStepCheckOnTrack2; cStepCheckOnTrack2: IF GVL.mover2.MCTOPLC.STD.CommandMode=MC_PLANAR_MOVER_COMMAND_MODE.OnTrack THEN state := cStepMover2MOveOnTrack2; END_IF cStepMover2MOveOnTrack2: GVL.mover2.MoveOnTrack(commandFeedback:=GVL.commandFeedbacks[0],GVL.tracks[2],targetPositionOnTrack:=250,constraint:=0,options:=MoveOnTrackOption); //test—- GVL.mover.MoveOnTrack(commandFeedback:=GVL.commandFeedbacks[0],GVL.tracks[2],targetPositionOnTrack:=250,constraint:=0,options:=MoveOnTrackOption); TON(IN:=TRUE,PT:=T#1S); IF TON.Q THEN IF GVL.mover2.MCTOPLC.SETONTRACK.SetPos>=249.9 AND GVL2RoboDK.xplanar2.pos.ActPos.x>=450.0 AND GVL2RoboDK.xplanar2.pos.ActPos.y>=222.0 THEN TON(IN:=FALSE); state:=cStepRobotCanPickMover2; END_IF END_IF; cStepRobotCanPickMover2: GVL2RoboDK.canPick:=TRUE; TON(in:=TRUE,PT:=T#0.2S); IF TON.Q THEN TON(IN:=FALSE); state:=cStepWaitRobotDoneMover2; END_IF cStepWaitRobotDoneMover2: IF GVL2RoboDK.Picked THEN GVL2RoboDK.canPick:=FALSE; state:=cStepMover2MoveBack; END_IF; cStepMover2MoveBack: GVL.mover2.MoveOnTrack(commandFeedback:=GVL.commandFeedbacks[0],GVL.tracks[2],targetPositionOnTrack:=0,constraint:=0,options:=MoveOnTrackOption); IF GVL.mover2.MCTOPLC.SETONTRACK.SetPos>=599.9 THEN state:=cStepMover1JoinTrack2; END_IF cStepMover1JoinTrack2: GVL.mover.JoinTrack(0, GVL.tracks[2], 0, 0); IF GVL.mover.MCTOPLC.STD.CommandMode=MC_PLANAR_MOVER_COMMAND_MODE.OnTrack THEN state := cStepMover1MoveOnTrack2; END_IF cStepMover1MoveOnTrack2: GVL.mover.MoveOnTrack(commandFeedback:=GVL.commandFeedbacks[0],GVL.tracks[2],targetPositionOnTrack:=250,constraint:=0,options:=MoveOnTrackOption); IF GVL.mover.MCTOPLC.SETONTRACK.SetPos>=249.9 AND GVL2RoboDK.xplanar1.pos.ActPos.x>=450.0 AND GVL2RoboDK.xplanar1.pos.ActPos.y>=222.0 THEN state:=cStepRobotCanPickMover1; END_IF cStepRobotCanPickMover1: GVL2RoboDK.canPick:=TRUE; state:=cStepWaitRobotDoneMover1; cStepWaitRobotDoneMover1: IF GVL2RoboDK.Picked THEN GVL2RoboDK.canPick:=FALSE; state:=cStepMover1MoveBack; END_IF cStepMover1MoveBack: GVL.mover.MoveOnTrack(commandFeedback:=GVL.commandFeedbacks[0],GVL.tracks[2],targetPositionOnTrack:=0,constraint:=0,options:=MoveOnTrackOption); IF GVL.mover.MCTOPLC.SETONTRACK.SetPos>=599.9 THEN state:=cStepMover2MOveOnTrack2; END_IF END_CASE GVL.mover.Update(); GVL.mover2.Update(); GVL.tracks[1].Update(); GVL.tracks[2].Update(); |

Result

Soure Code

Please download the source code from this link.

https://github.com/soup01Threes/TwinCAT3/blob/main/TwinCAT%20Project%20xplarn2.zip